There are three main strategies most facilities follow when it comes to machine maintenance: preventive maintenance (PM), predictive maintenance (PdM), and corrective maintenance (CM). Some consider breakdown maintenance (BM) as a fourth type, but unlike the first three, it does not require regular implementation.

Here, we define the three main types of machine maintenance strategies. We’ll also cover how and when to apply them in your maintenance program.

1. Preventive Maintenance (PM)

Preventive maintenance is a type of machine maintenance that aims to prevent machine failure and breakdown, as you can infer by its name. This prevention is possible through routine inspections. Depending on the results of these inspections, PM may involve additional repairs, parts replacement or tightening, lubrication replenishment or change, recalibration, etc.

PM inspections and the additional work necessary to keep the machine in top working condition can be performed on schedule during regular machine shutdowns. Depending on the type of machine or equipment, the criticality of the PM work, and the operational demands, facilities can execute PM weekly, monthly, bi-annually, or annually.

PM work can also be done whenever an opportunity arises. When a machine undergoes minor repair, technicians can perform additional PM work, taking advantage of the machine’s downtime and availability for maintenance.

Facilities can perform PM tasks using in-house technicians or by hiring third-party services. When to use or not to use your in-house technicians depends on their technical expertise and the type of PM work required.

2. Predictive Maintenance (PdM)

Predictive maintenance shares a similar objective with PM in that it also aims to prevent future machine failures. PdM differs from PM by its testing and data-gathering methods to predict the likelihood of machine failure or breakdown. Unlike PM, PdM can detect signs of failure that cannot be detected by regular inspection or check-ups.

The common PdM methods include oil analysis and vibration analysis. Oil analysis involves taking oil samples from a lubrication system and testing them for signs of contamination. Contamination levels show insight into the wear and tear of a machine and predict when it is likely to fail or break down.

Vibration analysis is a common PdM for machines with rotating components. This analysis involves using vibration signals to detect any anomalies in the vibration signature of a machine. Analyzing vibration provides insight into the machine’s balance, alignment, bearing condition, cavitation, etc.

Other PdM methods include visual inspections, electrical monitoring, acoustic and ultrasonic detection, thermography, and corona detection. PdM methods can be expensive, that’s why most facilities only carry them out annually or semi-annually. The frequency can increase if the machine shows critical signs of failure.

Although costly, performing PdM can save on machine failure costs and productivity losses. In addition, excellent PdM results can allow you to reduce the frequency of PM inspections.

3. Corrective Maintenance (CM)

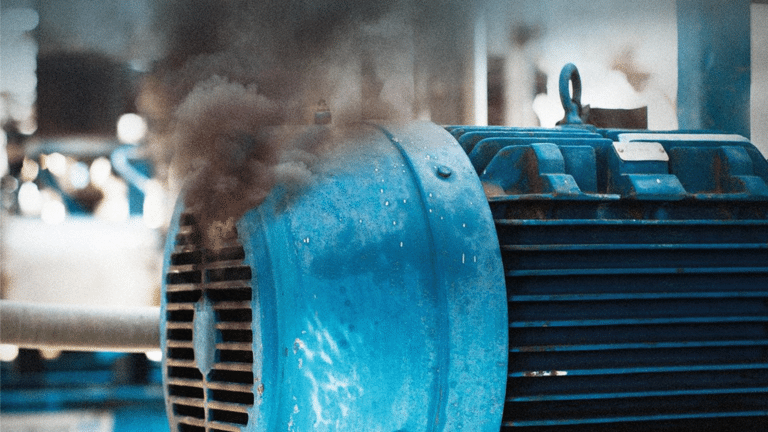

Unlike PM and PdM, corrective maintenance is performed after signs of failure or breakdown are already evident. CM can take many forms and can be performed at irregular and varying frequencies.

Corrective maintenance tasks are inexpensive, requiring minimal materials, tools, or technical expertise. In addition, most CM tasks require short downtime and cause minimal disruptions in operations. Because of these advantages over PM and PdM, CM is often favored for regular machine maintenance.

But relying too much on corrective maintenance is not cost-effective. Minimal but constant work on machines does not treat the machine issues at their root causes. These issues and malfunctions will escalate in severity over time and result in more expensive repairs and longer downtime in the future. If you wait for signs of failure before you deal with your machines, there will come a point where the failure becomes irreparable.

Optimize Machine Maintenance with Redlist’s CMMS

The three main types of machine maintenance discussed above are valuable strategies that should be included in every maintenance program. When used together, these methods make your maintenance program flexible against different sources of asset failure. But managing interconnected maintenance strategies can be complex for manual maintenance management. This is where you need a computerized maintenance management system (CMMS) like Redlist.

Redlist lets you plan unique PM, PdM, and CM strategies customized to your current programs. Flexible and highly integrative, Redlist can easily adjust to your ever-changing machine maintenance needs. With powerful computing technology and a user-friendly interface, Redlist’s CMMS helps you handle multiple strategies and analyze data for faster results-based decision-making. Redlist is your all-in-one tool for managing simple or complex maintenance systems. Sign up for a free demo with Redlist now!