Enterprise Asset Management Software

Comprehensive Visibility Into Asset Health & Performance

Transform the management of your assets and the critical resources needed to prevent costly downtime and improve overall equipment efficiency, all within a flexible solution made for high-performance maintenance teams.

Gain Control Of Your Asset Management

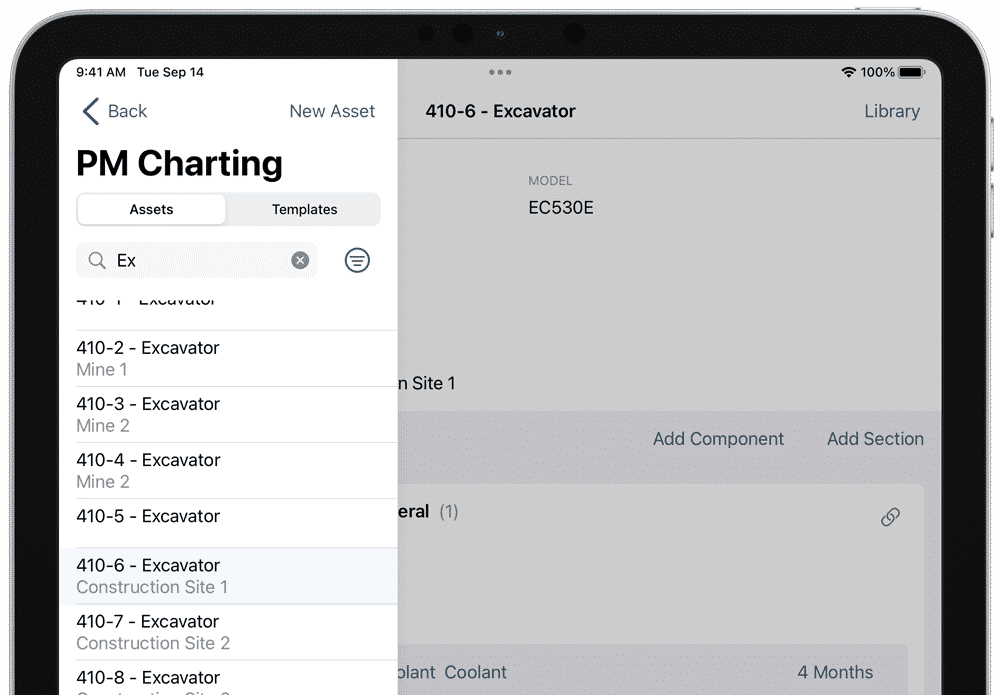

Asset Management

Automate critical maintenance intervals and transform from reactive to predictive maintenance.

Save Valuable Time

Eliminate wasted time from paper forms, looking for parts, double data entry, and the endless game of phone tag.

Increase Accountability

Assign specific people to maintenance tasks and get the peace of mind that your assets perform as expected.

Parts Inventory

Measure the effectiveness of your maintenance program and identify opportunities for savings.

Asset Management

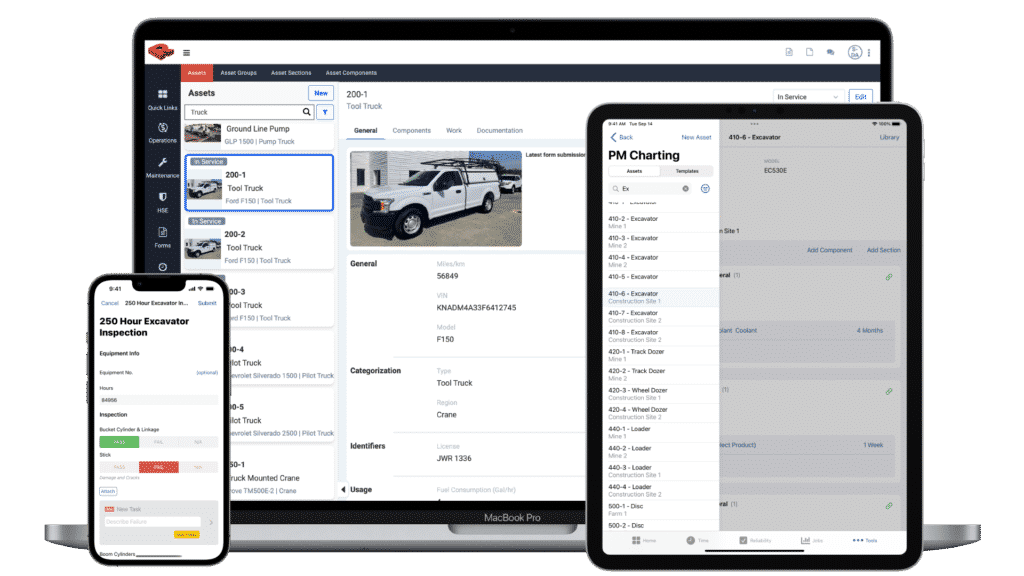

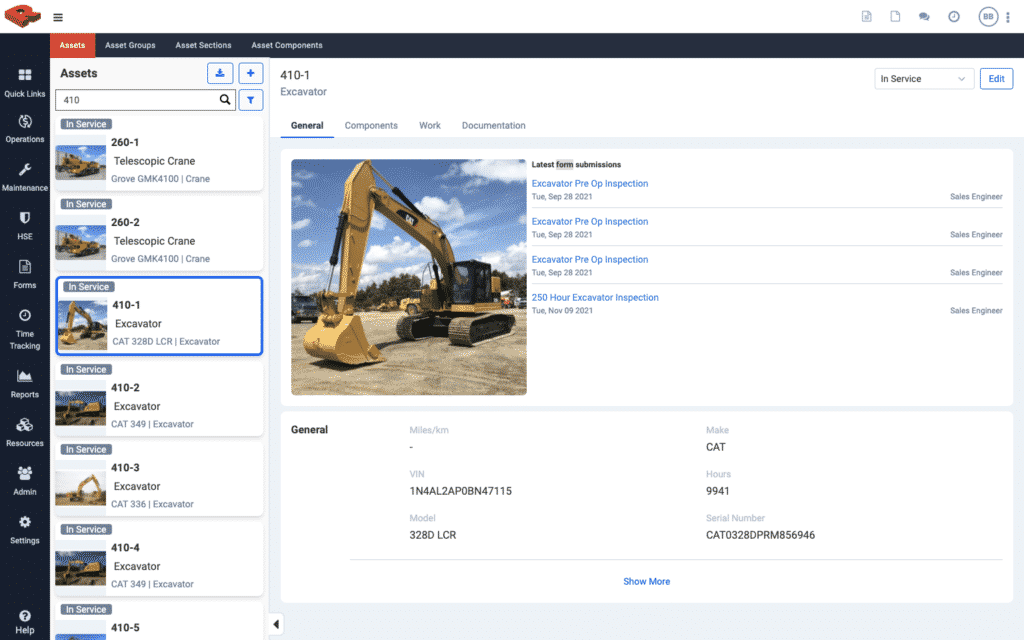

Monitor Physical Assets in One Platform

From preventive maintenance tasks, people, tools and parts. Direct and manage your entire maintenance team from one platform.

Asset Details

Location

Attachments

Inspection History

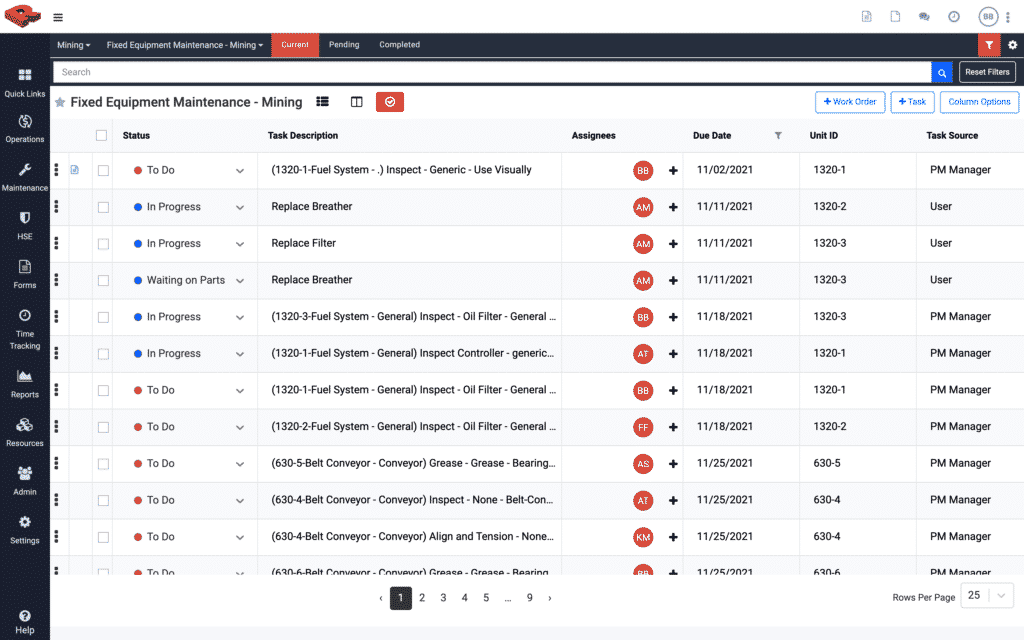

Work Order Management

Configure to Your Unique Needs

Utilize powerful work order tools to create a framework for your unique process and provide your team with a rugged app to document tasks.

Frequency

Assignments

Templates

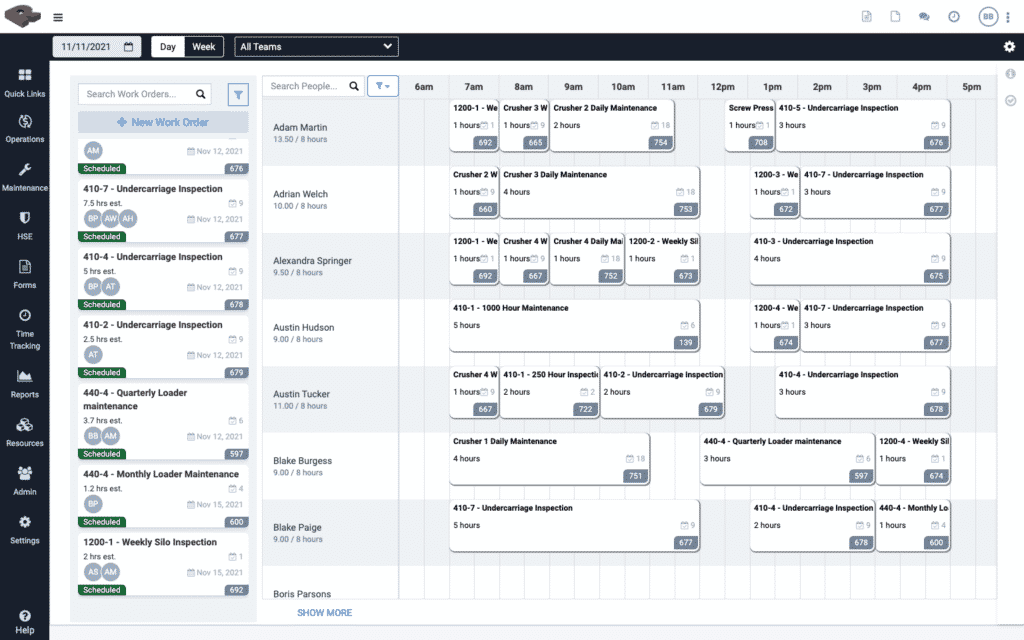

Resource Management

Quickly Coordinate Resources

Boost efficiency by planning maintenance schedules so that you always have the time, people, parts and tools to keep assets running.

Time Tracking

Simplify On-boarding

Templates

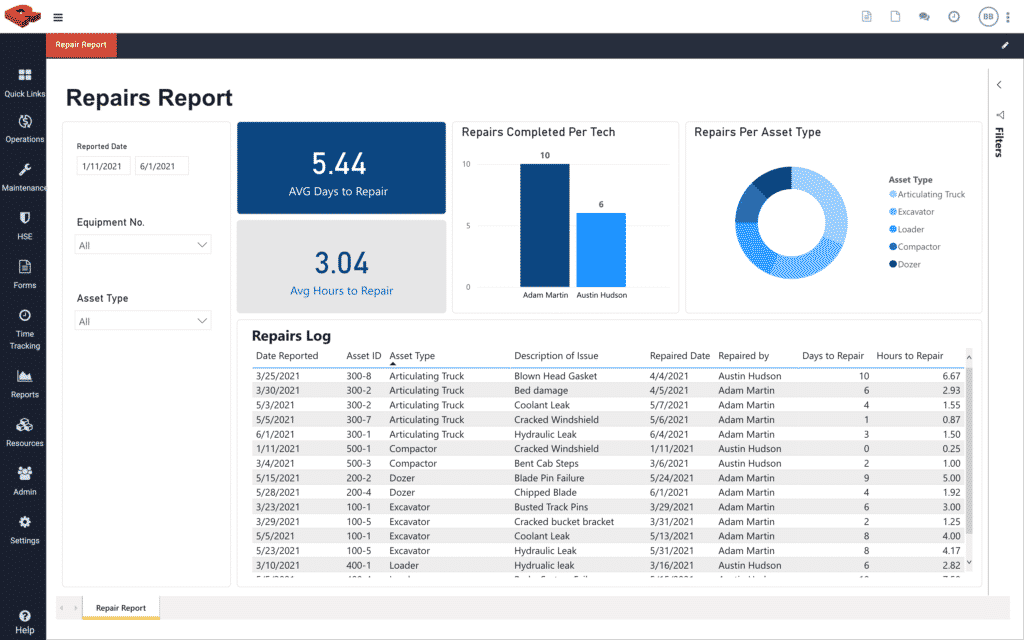

Business Analytics

Drive Asset Performance with Clear Asset Data

Gain real-time visibility into your business and save time from double data entry. With robust reporting, you can act upon trends faster and accelerate the growth of your business.

Get Common Reports On Key Maintenance KPI's In Real-time

- Mean Time Before Failure (MTBF)

- Mean Time to Failure (MTTF)

- Mean Time to Repair (MTTR)

- Downtime Costing Reports

- Total Cost of Ownership (TCO)

- Fluid Leak Reports

- Repairs Reports

- Asset Health

- Maintenance Compliance

- Overall equipment effectiveness

- Percentage Emergency Work

- Turnover ratio

Lubrication Management

Manage your lubrication program and team with, detailed routes, automated PM programs and real-time digital inspections.

+ Included in Enterprise Asset Management

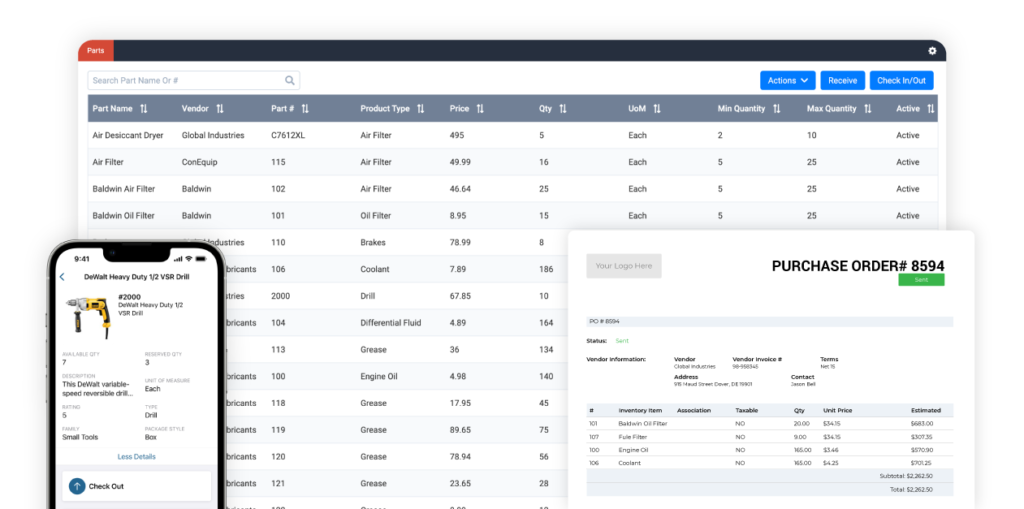

Purchasing & Inventory

Parts, Products & Productivity

Increase productivity throughout your organization by tracking your spare parts, products, and tools all within the same platform as the rest of your maintenance.

Remove the guess work of inventory management

Manage Vendors

Cut costs by managing regular/preferred vendors and ensuring you get the best price.

Item Images

Provide clear visual references for your team for more accurate item selection

SKU & Parts Numbers

Specify SKU# and part numbers to give exact details on what item needs to be used.

Assign Products

Attach parts/products/tools to maintenance tasks for increased accountability.

Multi Location Inventory

Oversee inventory across multiple locations without the hassle of multiple systems.

Part Locations

Enhance efficiency by providing your team with detailed locations by row, shelf, or bin.

Add Sales Markup %

Manage parts sales with sales markup and get better visibility into sales goals.

Set Part Alternatives

Link alternative parts together and utilize what you have on hand to get the job done.

Multi Level Catagories

Organize items into multi-level categories to better manage large inventory lists.

Min Max Alerts

Manage stock levels with automated alerts based on quantity minimums.

Automate PO Creation

Automatically trigger P.O''s to be created when quantities fall below minimums.

Costing

Compaire costs between vendors and measure repair costs per asset.

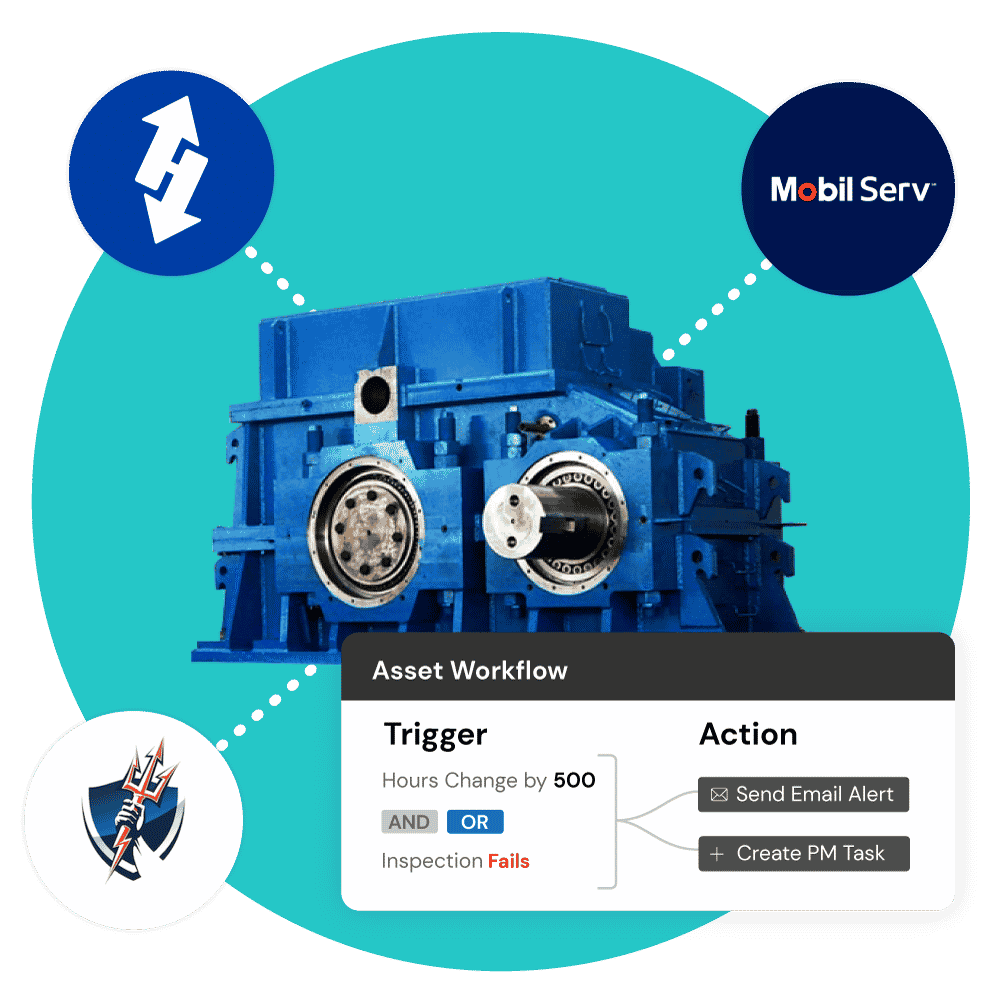

Connect Data to Established Systems

Sync IoT sensors, GPS trackers, and oil analysis labs. Improving communication and propelling your company into the age of Industry 4.0.