Lubrication Management Software

Attain Equipment

Reliability

With Redlist

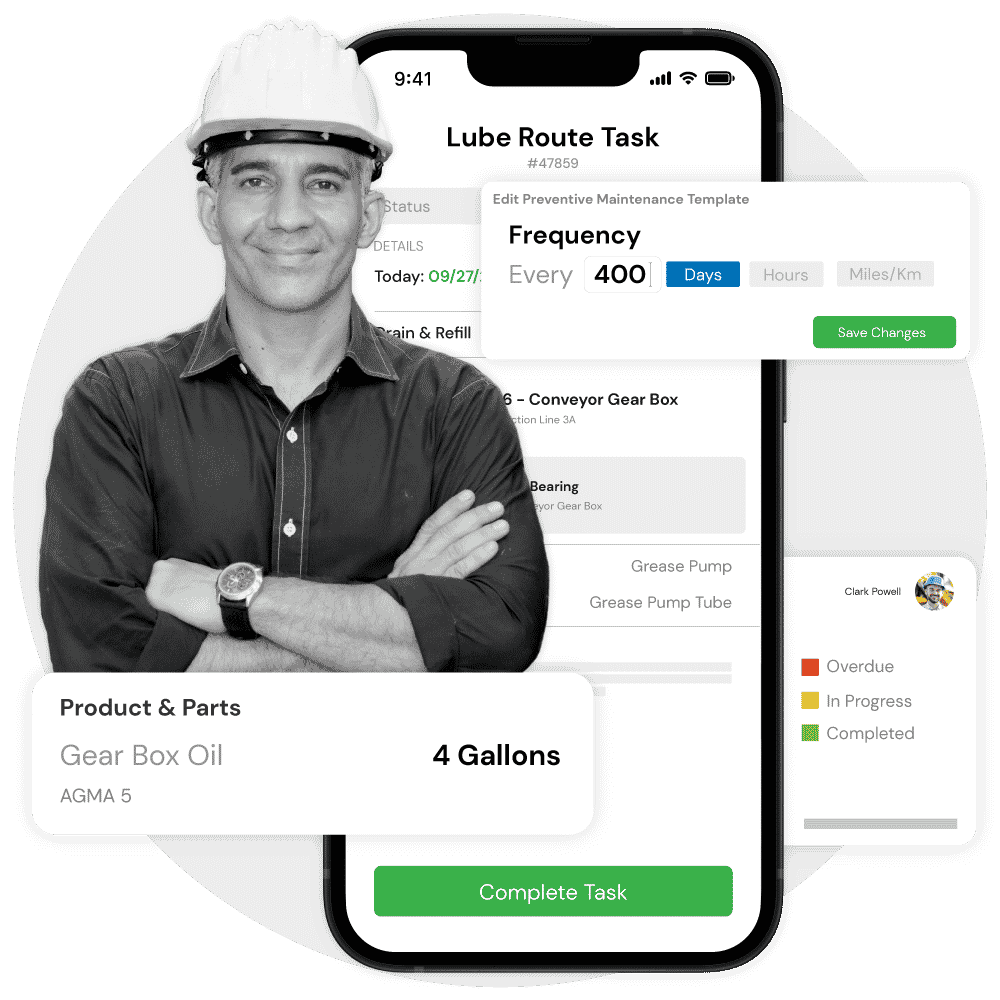

In weeks, have a fully charted and organized system complete with photos, documents, work instructions, oil and grease products, and estimated completion times for every lubrication point in your facility all in a mobile device that is already in your pocket.

Create an Expert Lubrication Program Strategy

Take the guess work out of reliability and let our certified lubrication team chart your facility on-site and have a program in weeks.

Free 30 Min Reliability Consultation

With a CLS Certified Lubrication Engineer

Implement Your Lubrication Management Program

Ensure proper lubrication for all of your assets & increase adoption with simplified workflows and time saving automations.

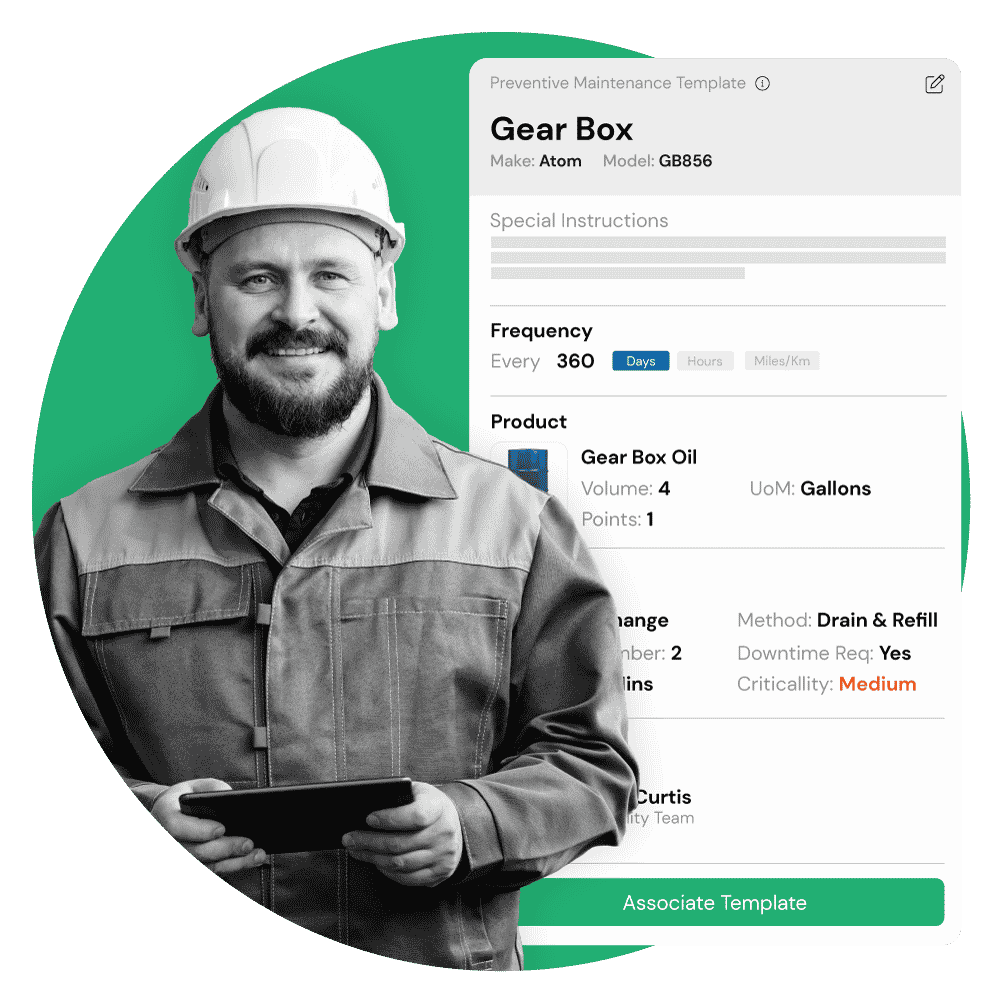

Improve PM Implementation

Detailed Lubrication Methods

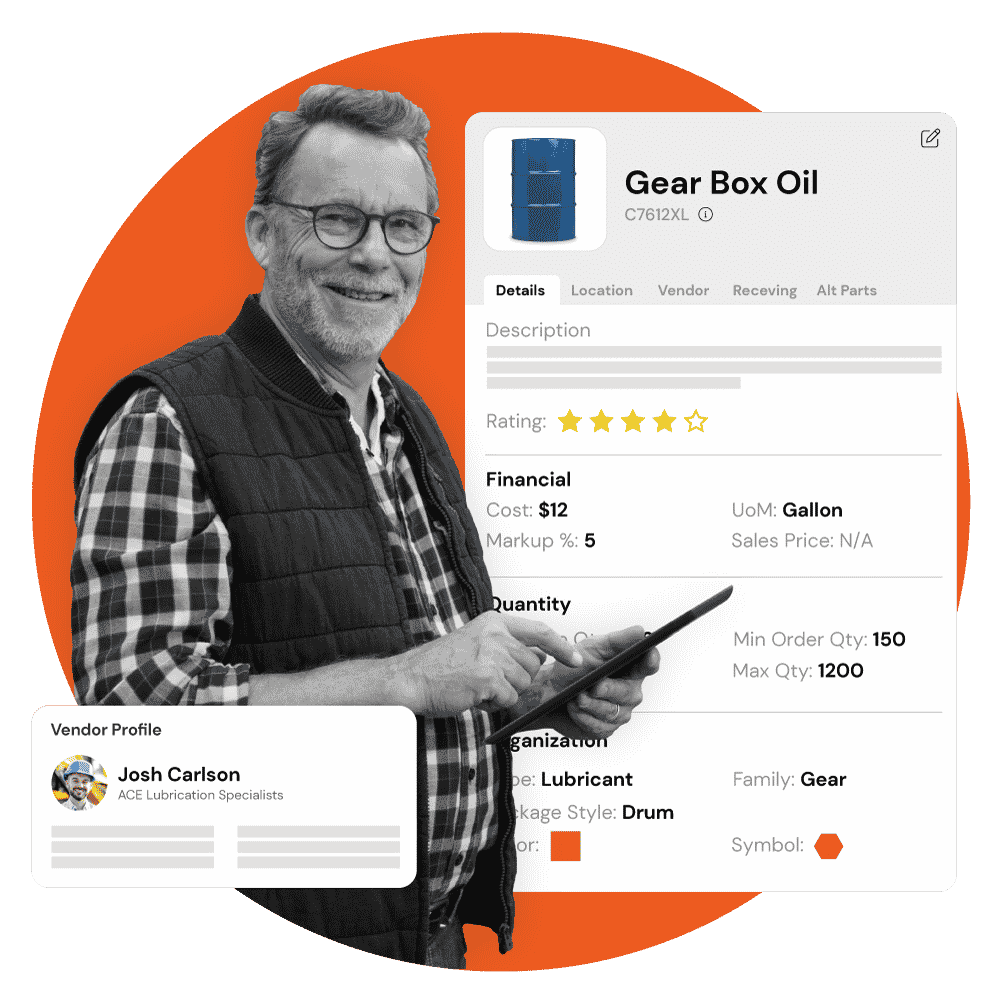

Accurately Manage & Monitor Lubricant Inventory

Improve inventory accuracy with real-time mobile updates to inventory levels when PM tasks are completed by reliability team members.

Lubricant Purchasing & Receiving

Vendor Management

Get Actionable Analytics & Improve Overall Reliability

Gain visibility into the health of your lubrication program, perform A/B testing and quickly adjust PM templates in a few clicks to drive continuous improvement.

Accelerate Continuous Improvement

Monitor Reliability KPI's

Mobile Tools For Reliability & Lube Management Teams

Increase route compliance with Redlist’s easy-to-use mobile app & provide techs everything they need to accurately complete reliability tasks the same way every time.

- Daily Task/Route Manager

- Detailed Task Instructions

- Time Tracking

- Photo Inspections

- QR Code Scanner

Include Details at the Task Level

With Redlist’s lubrication management, task instructions are placed at the task level. Which gives teams more flexibility to configure Redlist to meet the specific needs of their lubrication program.

Lubricant

Lube Points

Lubricant Qty

Frequency

Digital Forms

Time Tracking

Task Comments

Reference Documents

Custom Instructions

Photos

Collaboration

Notifications

Task Assignments

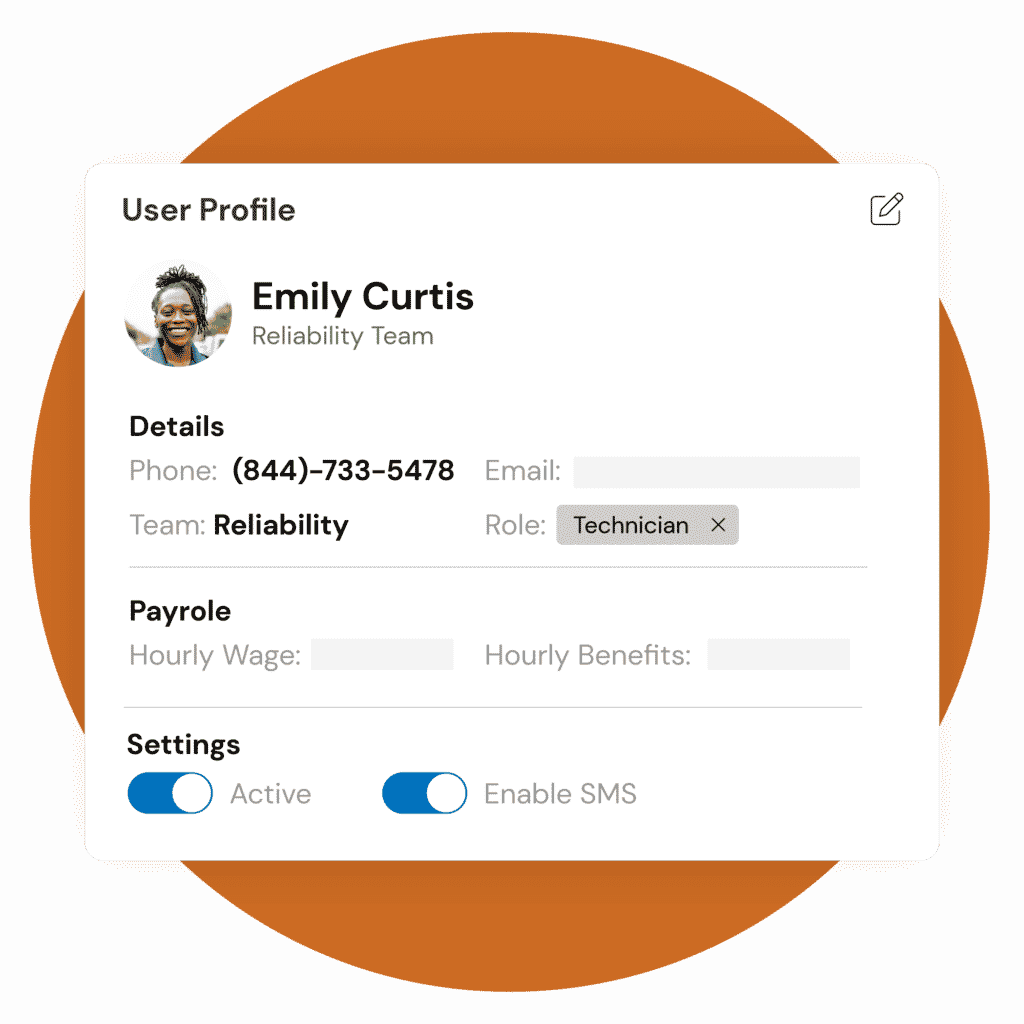

Team Management

Shorten onboarding with Redlist by quickly inviting team members and giving them access to all the tribal knowledge they need to start contributing to your reliability program.

Time Tracking

Certifications

Comments

Text Alerts

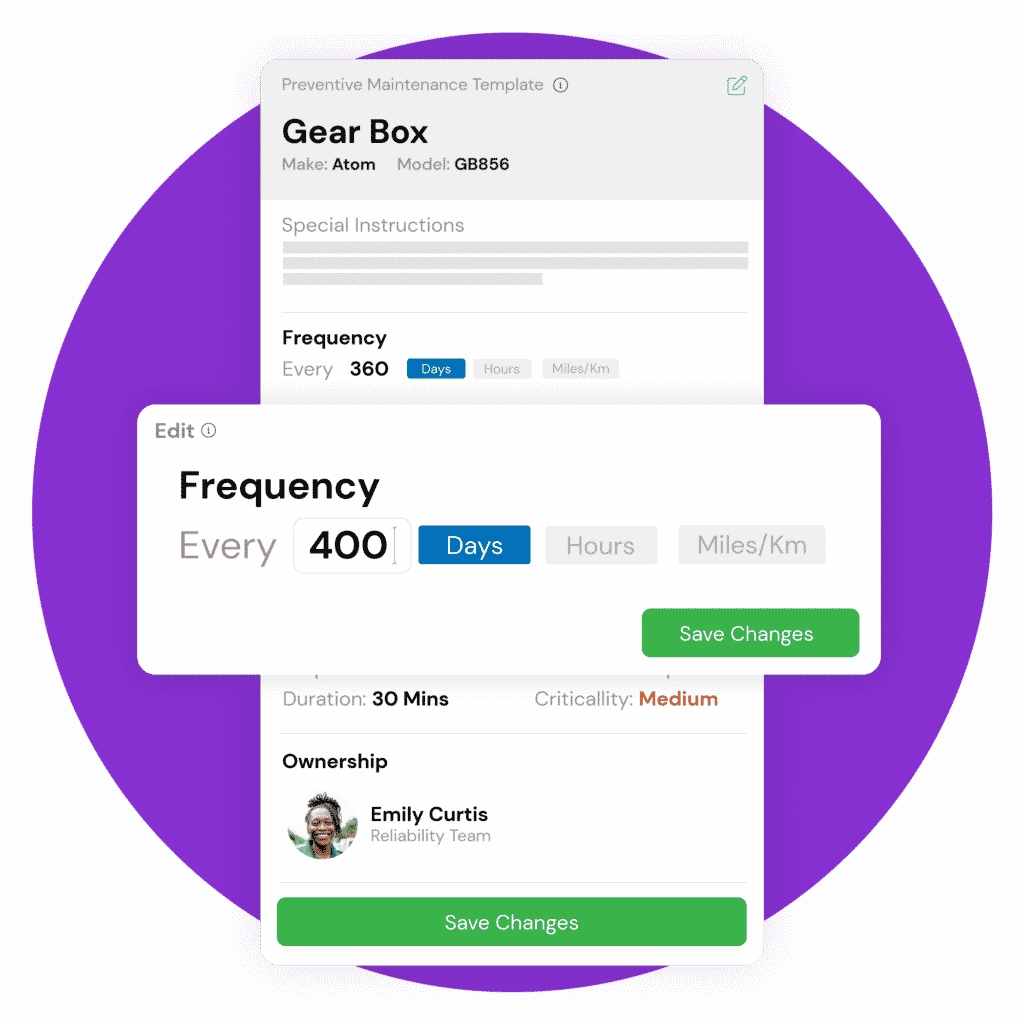

Quickly Adjust PM Templates

Optimize your lubrication practices faster and reduce maintenance costs by adjusting PM templates and applying changes to multiple assets in minutes.

Reliability A/B Testing

Extend Lubricant Life

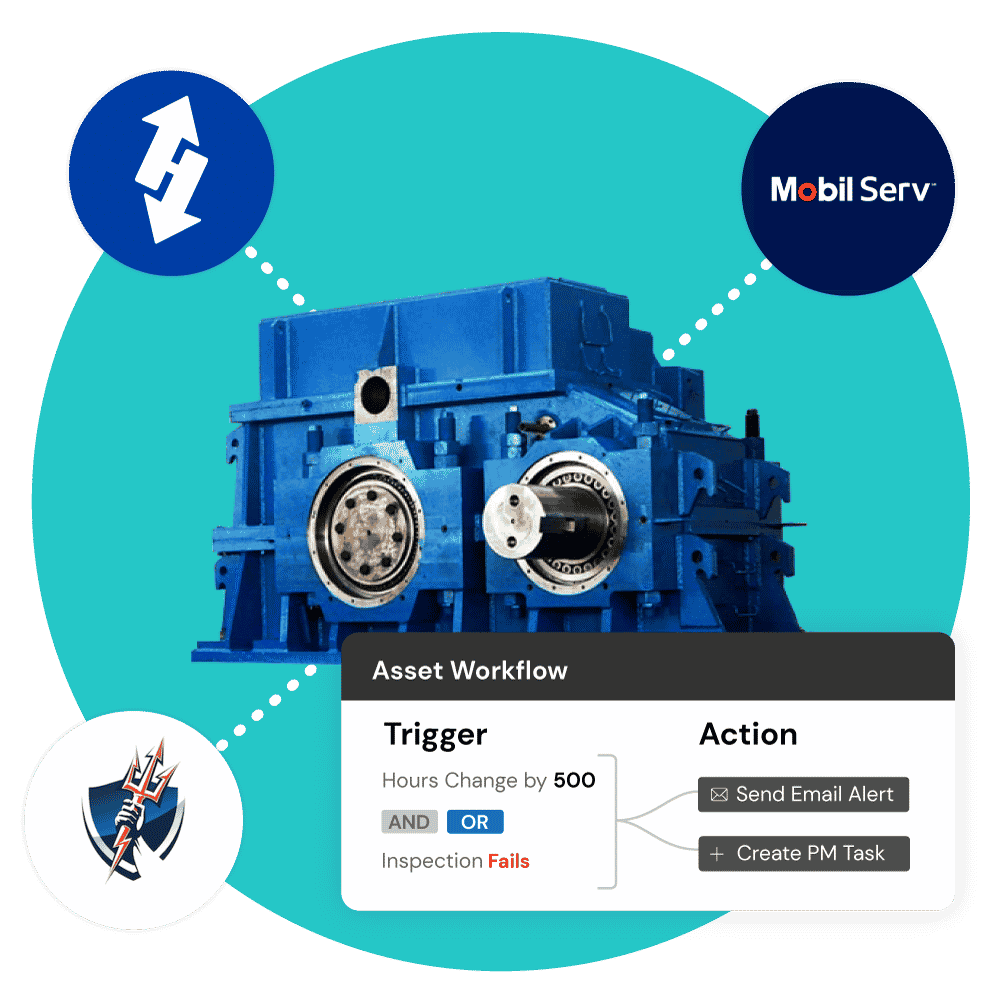

Extend Equipment Life With Integrations & Condition Monitoring

Connect to established business management systems, IoT sensors, GPS trackers, and oil analysis labs. Improving communication and propelling your company into the age of Industry 4.0.

Engineering Services & Support

With Redlist, you get a reliability partner that stands by you every step of the way. Sharing years of specialized experience in lubrication management to help you achieve your reliability goals.

Recent Lubrication Management Posts

The ROI of Implementing Lubrication Management Software into your Business

Explore the substantial financial and operational benefits of integrating Lubrication Management Software (LMS) into your business processes.

Guide to Additives in Lubricants

Most lubricants on the market today contain some sort of additive. But, what are these additives, and what do they do? In this guide, we’ll take a look at some of the more common additives found in lubricants, and explain their function.

Choosing the Best Lubrication Management Software for Your Industry

This comprehensive blog post guides you through selecting the best lubrication management software and how it can help your business grow.

Customer Stories

Learn how customers have used Redlist lubrication management to identify savings opportunities and better manage their reliability program.

Lubrication Management FAQ's

If you have other general questions or need help with your lubrication management program speak with one of our CLS certified lubrication consultants.