In the world of heavy machinery and industrial equipment, reliability is paramount. Ensuring that your equipment operates at peak performance for an extended period is not just about hefty investments; it’s about smart equipment maintenance. One crucial aspect of this is lubrication system maintenance.

This article will shed light on the significance of proper equipment maintenance, offer essential maintenance tips, and introduce you to Redlist, a leading lubrication management software company that can help you streamline your maintenance processes.

The Importance of Equipment Maintenance

Heavy machinery and equipment are the backbone of numerous industries, from construction to manufacturing. The reliability of these assets is essential to meeting production targets and avoiding costly downtime. To achieve this, equipment maintenance is non-negotiable.

Maintenance Tips for Equipment Longevity

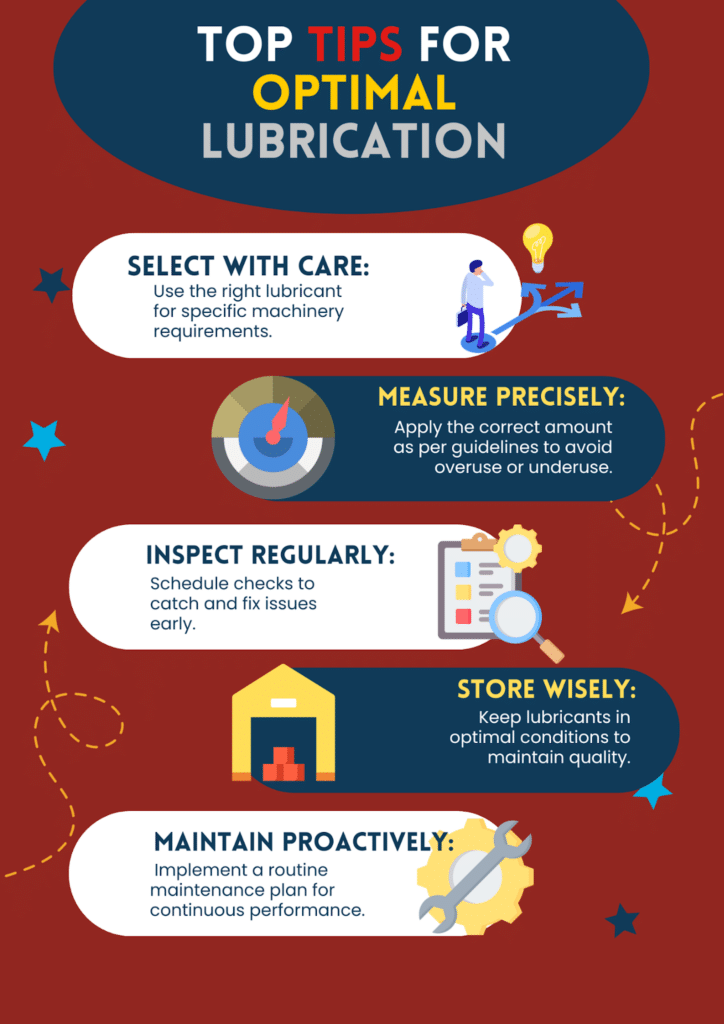

1. Regular Inspections: Establish a routine inspection schedule for your equipment. This should include checking for signs of wear and tear, loose components, and lubrication levels. Regular visual inspections can catch potential issues before they become major problems.

2. Proper Lubrication: Effective lubrication is key to equipment longevity. Ensure that all moving parts are adequately lubricated. Use the right type and amount of lubricant for each component, and follow manufacturer recommendations.

3. Training: Invest in training for your maintenance team. Properly trained technicians can identify issues early, perform maintenance correctly, and reduce the risk of accidents.

4. Predictive Maintenance: Implement predictive maintenance techniques, such as vibration analysis and thermography, to identify and address problems before they result in equipment failure.

5. Documentation: Maintain detailed records of equipment maintenance, including dates, procedures, and any replacements or repairs. This documentation is invaluable for tracking the health of your equipment and planning future maintenance.

Redlist: Your Lubrication Management Solution

Redlist is a leading lubrication management software company that specializes in simplifying equipment maintenance. Their software is designed to streamline the lubrication management process, making it easier for businesses to maintain equipment longevity.

Here’s why you should consider Redlist:

1. User-Friendly Interface: Redlist offers an intuitive and user-friendly interface, making it easy for your maintenance team to navigate and use effectively.

2. Customizable: The software can be customized to fit the unique needs of your business, ensuring it aligns with your specific equipment and maintenance requirements.

3. Predictive Maintenance: Redlist’s predictive maintenance features help you proactively identify issues, preventing costly breakdowns.

4. Mobile Accessibility: Access Redlist from anywhere, allowing your team to stay connected and informed, even when working remotely or on-site.

5. Free Demo: Redlist offers a free demo, so you can experience the software firsthand and see how it can revolutionize your equipment maintenance processes.

Proper equipment maintenance, including effective lubrication management, is crucial for achieving equipment longevity and reliability. By following the maintenance tips outlined in this article and considering a solution like Redlist, you can ensure that your heavy machinery and equipment continue to operate at their best, minimizing downtime and maximizing productivity. Don’t wait; book a free demo with Redlist today to discover how our software can help your business grow through streamlined maintenance processes.