In today’s fast-paced industrial environment, efficiency and productivity are paramount. This is where maintenance software and computerized maintenance management systems (CMMS) come into play. As a leading CMMS EAM software company, Redlist understands the critical role of maintenance in business operations.

In this quick guide, we will explore how maintenance software revolutionizes industrial maintenance, delve into various maintenance strategies, and highlight how Redlist’s CMMS can be a game-changer for your business.

Understanding Industrial Maintenance and Maintenance Software

Industrial maintenance refers to the practices and processes aimed at keeping equipment in optimal condition. Maintenance software, a digital cornerstone in this domain, streamlines these processes, making them more efficient and effective. Maintenance management, at its core, is about ensuring that equipment and assets are performing at their best, minimizing downtime, and extending their life cycle.

Exploring Maintenance Strategies

There are several types of maintenance strategies, each suited to different industrial needs. These include:

1. Preventive Maintenance – Regularly scheduled checks and repairs to prevent breakdowns.

2. Predictive Maintenance – Using data and analytics to predict when maintenance should be performed.

3. Reactive Maintenance – Addressing issues as they arise.

4. Reliability-Centered Maintenance (RCM) – A strategy focused on understanding the functions and potential failures of assets for more effective maintenance.

The Role of CMMS in Maintenance Management

A CMMS like Redlist’s software elevates maintenance management by offering a centralized platform for managing maintenance tasks, tracking inventory, and analyzing performance data. This integration of data and operations leads to more informed decision-making, ultimately boosting production efficiency.

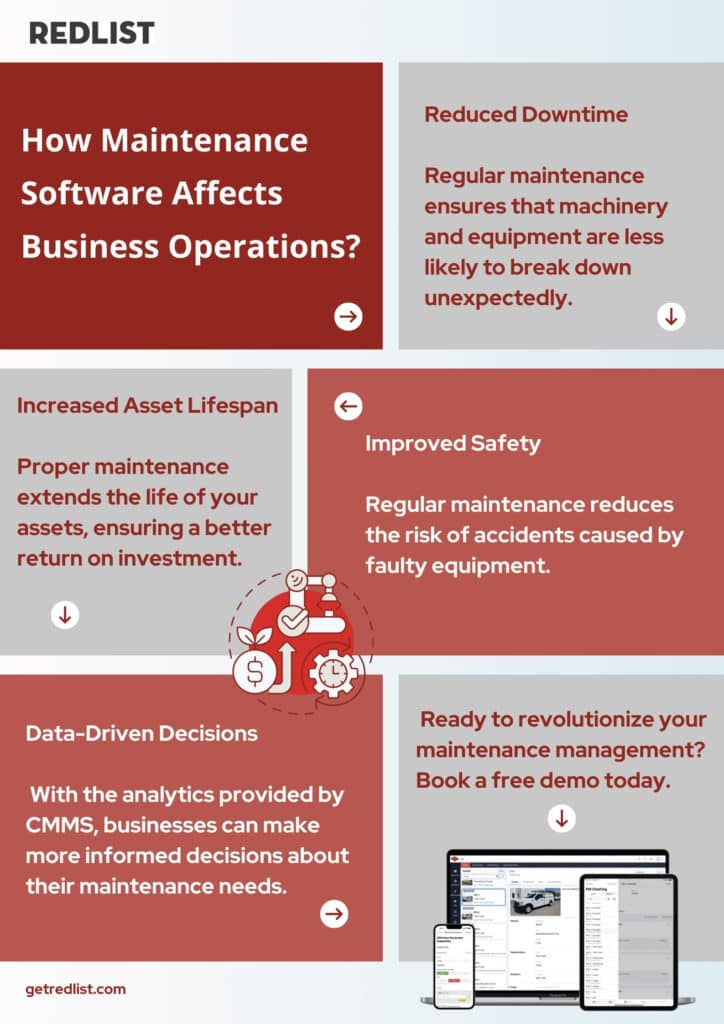

How Maintenance Software Affects Business Operations?

Maintenance of software impacts various aspects of business operations, including:

Redlist’s CMMS: Your Partner in Maintenance Excellence

Redlist’s CMMS stands out in the maintenance software market. It’s not just about what maintenance management is; it’s about redefining it. Our solution offers:

1. User-Friendly Interface: Easy to navigate and use, even for those not tech-savvy.

2. Customizable Features: Tailor your maintenance strategy to fit your unique business needs.

3. Robust Analytics: Gain insights into your maintenance operations to continually improve processes.

4. Mobile Accessibility: Manage your maintenance tasks on the go, enhancing flexibility and responsiveness.

In conclusion, the right maintenance software and CMMS solution can transform your maintenance management, leading to significant gains in efficiency and productivity. Understanding the definition of industrial maintenance and embracing the right maintenance strategies are critical steps in this journey. Redlist’s CMMS offers a robust, user-friendly solution that addresses these needs and more.

Are you ready to experience how Redlist can revolutionize your maintenance management? Book a free demo today and step into a world of streamlined maintenance, enhanced efficiency, and operational excellence.