Redlist: Oil and Gas Asset Management Software That Maximizes Uptime

Unify preventive, predictive, and autonomous maintenance strategies to protect critical assets, meet compliance, and empower your workforce.

Purpose-Built for Oil & Gas Reliability

From offshore rigs to refineries, the oil and gas industry demands precision, safety, and operational continuity. Redlist unifies preventive, predictive, and autonomous maintenance while digitizing work and processes end to end.

Beyond reliability engineers, maintenance superintendents, and plant managers, Redlist empowers the entire organization by integrating seamlessly with your existing tech stack, including ERP, IoT, oil analysis, and more, to create clean, standardized data as a single source of truth. The outcome: fewer unplanned outages, quicker onboarding, and improved compliance without siloed systems.

Core Pillars of Oil & Gas Asset Management Success

Holistic Reliability Strategy

Offline-First, Ruggedized Mobility

Built Around Lubrication Excellence

Rapid Deployment with Low Overhead

Connects Data Across the Enterprise

Resilient Knowledge Retention

How Redlist Transforms Asset Management in the Oil & Gas Industry

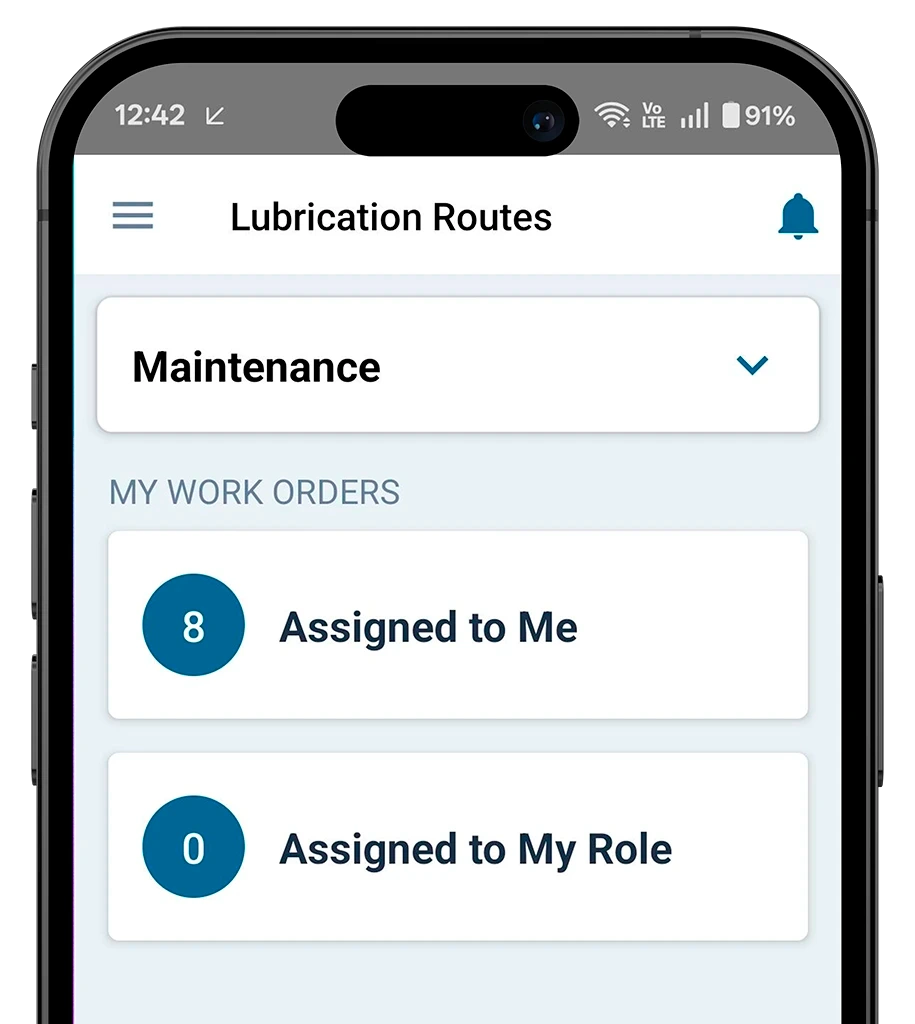

Lubrication Management (LMS): Eliminate Failures at Their Root

Lubrication failures are a leading cause of unplanned downtime in oil and gas affecting compressors, turbines, pumps, and rotating equipment across upstream production, midstream transport, and downstream refining. Redlist’s lubrication management software (Lube Engineering, Route Pro, and Oil Analysis Monitoring) ensures that every lubrication point receives the right care, on time, every time:

Automated Lubrication Routes for Compressors and Turbines

Standardize and automate lubrication tasks on mission-critical assets such as gas compressors, turbines, and pump trains. Prevent missed lube points with GPS-verified routes, completion tracking, and photo-based proof-of-presence.

Wellhead and Pump Jack Lubrication Compliance

Digitally assign lube points on remote wellheads and pump jacks. Verify completion even in low-connectivity environments with Redlist’s offline mobile capability. Improve safety and accountability for field technicians working across dispersed assets.

Pipeline Pumping Station and Valve Lubrication

Create integrated lubrication schedules for pipeline pump stations and valve assemblies. Reduce seizure and leakage risks through centralized scheduling, automatic compliance alerts, and route dashboards.

Refinery Rotating Equipment Reliability

Streamline lubrication routines for critical refinery assets like blowers, fans, and heat exchangers. Minimize bearing and seal failures with centralized scheduling, compliance dashboards, and immediate escalation for overdue tasks.

Cross-Site Standardization

Unify lubrication practices across upstream, midstream, and downstream facilities in a single platform. Simplify technician training, route planning, and compliance tracking to ensure consistency across your enterprise.

See how Redlist helps oil and gas operators reduce downtime and improve compliance with lubrication management.

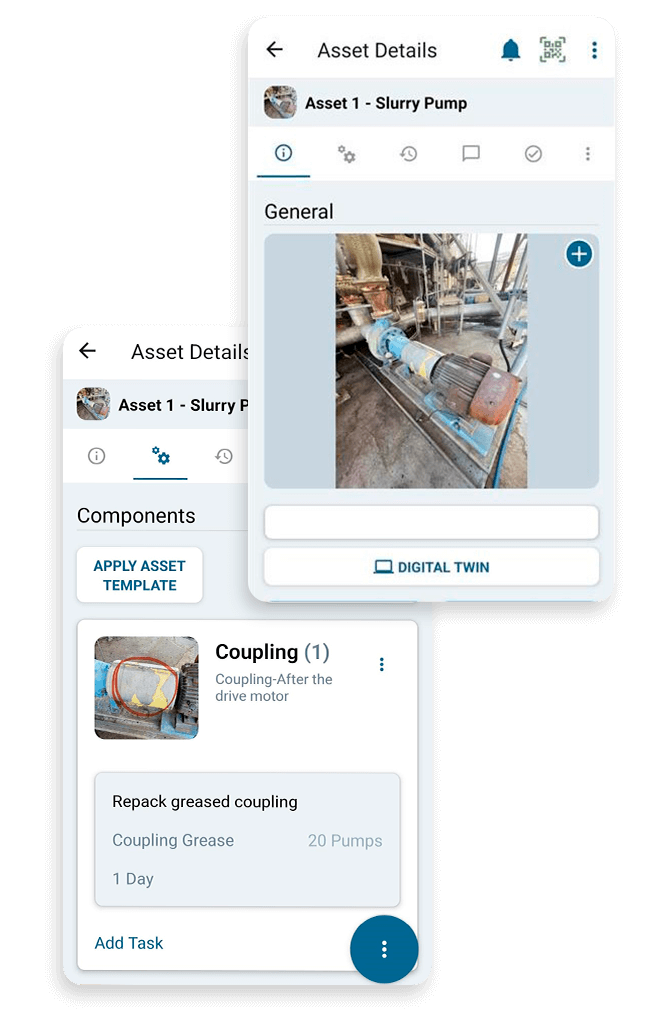

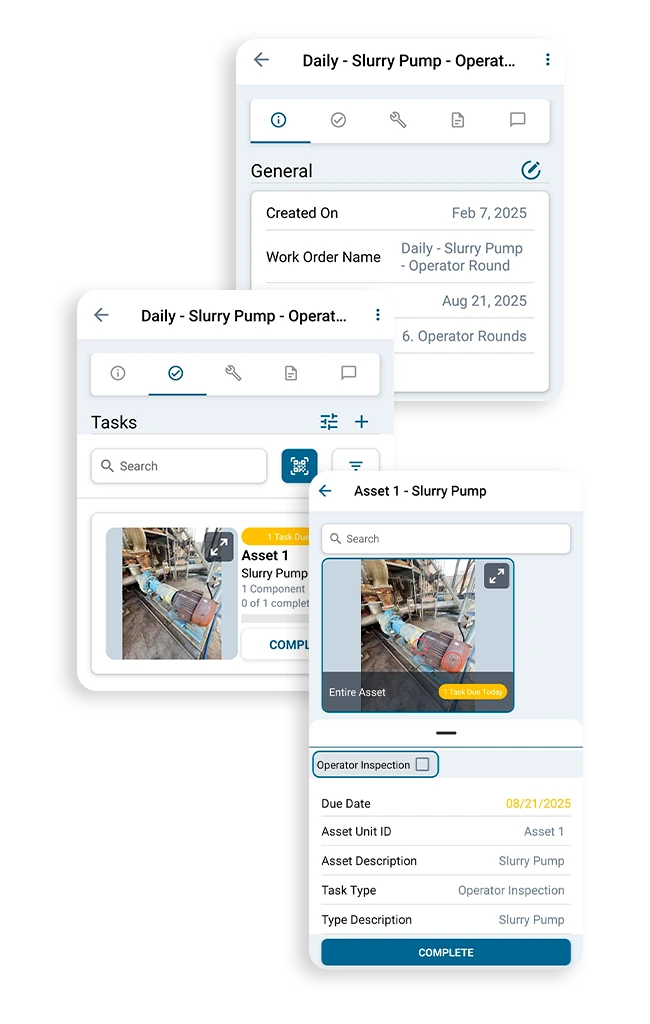

Operator Basic Care (OBC): Embedding TPM in Oil & Gas Operations

In the oil and gas industry, operators are the first line of defense against costly failures. Pumps, compressors, turbines, and wellheads often show early signs of wear including leaks, vibration, and overheating long before catastrophic breakdowns occur. Redlist’s Operator Basic Care (OBC) tools bring Total Productive Maintenance (TPM) to life by empowering frontline operators to share ownership of asset reliability:

CIL Checklists for Daily Rounds

Provide operators with digital Clean, Inspect, Lubricate (CIL) checklists tailored to drilling rigs, pump stations, and refinery systems. Standardize operator-led maintenance to catch issues before they escalate.

Anomaly Capture and Rapid Reporting

Enable operators to instantly log leaks, unusual vibrations, or abnormal temperatures from mobile devices even while they are offline. Anomalies feed directly into Redlist workflows for real-time maintenance response.

Integrated Workflows Across Ops and Maintenance

Break down silos by connecting operators and maintenance teams through shared digital workflows. Operators can escalate issues directly, while reliability teams track, assign, and resolve them efficiently.

Safer, More Accountable Operations

Give operators access to step-by-step SOPs and mobile safety checks to ensure tasks are performed correctly and logged automatically. Increase compliance while reducing risk of human error in high-hazard environments.

Culture of Shared Reliability

Shift from “maintenance-only responsibility” to a site-wide culture of reliability. With OBC, every operator becomes an active participant in asset care, boosting uptime and extending equipment life.

By embedding TPM principles, every operator becomes a first-line asset guardian, reducing reactive maintenance calls and extending asset life.

Enterprise Asset Management (EAM): Bridging ERP and Field Operations

In the oil and gas industry, ERP systems are critical for financial and supply chain management, but they often fall short in providing the field-level asset visibility required to maintain uptime. Redlist’s Enterprise Asset Management (EAM) fills this gap, delivering the insights and control needed to keep critical assets reliable and compliant:

Centralized Asset Data and Lifecycle History

Consolidate all records—from compressors and turbines to wellheads and refinery units—into a single source of truth. Track performance, maintenance history, and lifecycle costs to make smarter operational decisions.

ERP, SCADA, and IoT Integration

Bridge the divide between corporate systems and field operations. Redlist integrates directly with ERP, SCADA, and IoT sensor networks, ensuring maintenance teams have real-time asset health data at their fingertips.

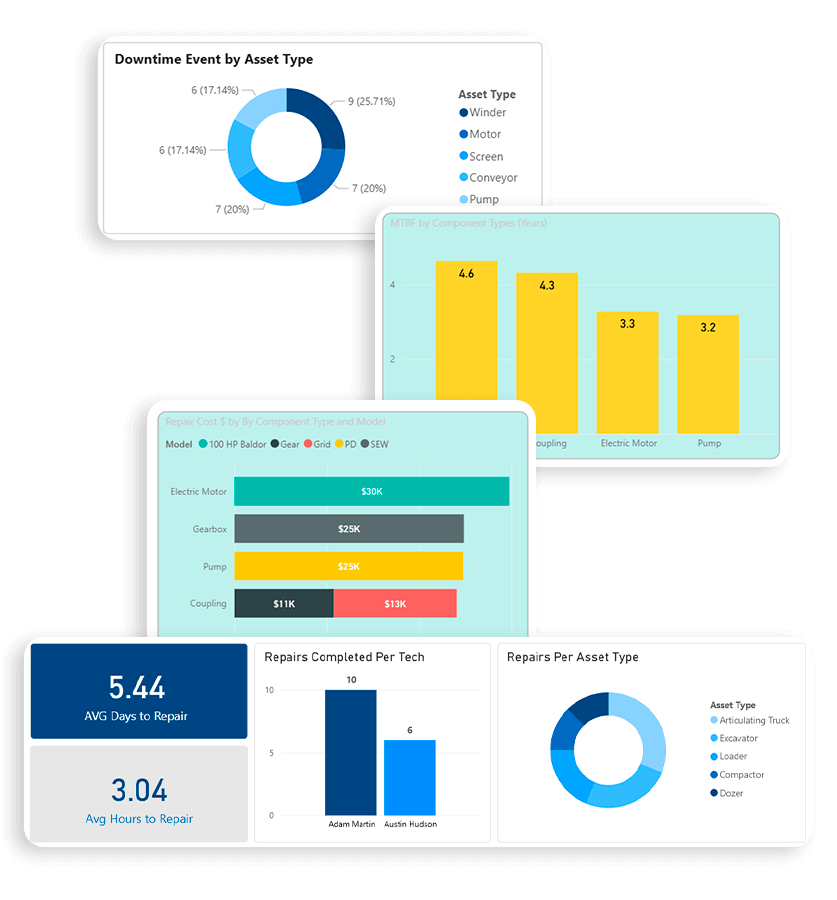

CapEx-Driven Reliability Planning

Tie reliability metrics into capital planning. Use Redlist’s analytics to forecast repair vs. replace decisions, optimize asset lifecycle management, and align operational strategy with financial objectives.

Multi-Site Asset Visibility

Standardize maintenance practices across upstream fields, midstream pumping stations, and downstream refineries. Gain consistent oversight and benchmarking across the entire enterprise.

Reduce Risk of Equipment Failure

By closing the gap between ERP reporting and field-level maintenance, Redlist ensures early intervention—protecting uptime, profitability, and safety.

Discover how an oil and gas company became a model for DEQ compliance while improving uptime with Redlist.

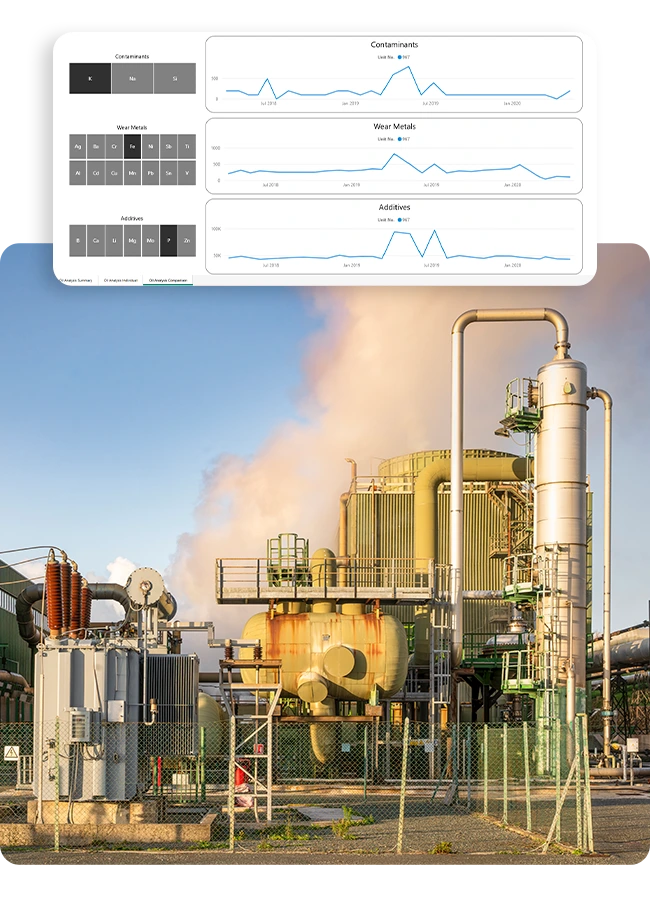

Predictive Pro: Condition-Based Intelligence

In oil and gas, the cost of unexpected downtime isn’t limited to lost output it can create environmental risks, safety hazards, and regulatory fines. Redlist’s Predictive Pro suite equips reliability teams with the tools to detect failures long before they happen, so operations stay safe and uninterrupted:

Real-Time Sensor Data

Ingest vibration, temperature, and acoustic data from IoT-enabled assets like compressors, turbines, and pumps. Identify abnormal operating conditions immediately.

Oil Analysis Integration

Combine predictive sensor trends with oil sampling results to uncover wear patterns, contamination, or lubrication breakdowns. Build a complete picture of asset health.

Actionable Predictive Alerts

Automate alerts when conditions deviate from acceptable thresholds. Enable teams to intervene before a minor anomaly turns into a costly shutdown.

Asset Scoring and Benchmarking

Assign health scores to critical assets and benchmark performance across sites, ensuring your highest-value equipment receives the attention it deserves.

Discover how a mining customer used Redlist to integrate oil analysis and save over $270,000 annually in fluid loss. A result that translates directly to cost and compliance savings in oil and gas operations.

Workforce Enablement & Training Progressions: Build Skilled, Compliant Teams

High turnover, demanding compliance requirements, and the technical complexity of assets make workforce readiness one of the biggest challenges in oil and gas. Redlist’s Workforce Enablement tools ensure your operators, technicians, and contractors have the skills and guidance they need from day one:

Digital SOPs at the Task Level

Embed visual, step-by-step standard operating procedures directly into every work order. Reduce human error while giving new hires confidence to execute tasks safely and correctly.

Certification Tracking for Compliance

Monitor OSHA, EPA, and site-specific safety certifications in one place. Automate reminders for renewals and ensure audit readiness across all locations.

Just-in-Time Training Modules

Deliver training videos and micro-learning directly on mobile devices—even offline. Empower technicians to access knowledge where and when they need it most, whether on a rig, in a refinery, or at a pipeline station.

Skill Progression and Advancement

Track employee growth through structured training progressions. Retain top talent by offering clear pathways to advancement in reliability and maintenance roles.

Cross-Functional Reliability Culture

Bridge gaps between operations and maintenance teams by ensuring everyone has access to the same digital tools and training. Create a culture of shared ownership for asset reliability.

Ensure Consistent Work Quality Across the Fleet

See how Redlist can help you upskill, retain, and protect your workforce.

Integration Hub: Your Central Reliability Ecosystem

Oil and gas operations rely on a complex web of systems including ERP, SCADA, IoT sensors, vendor portals, and more. Without integration, critical reliability data stays siloed, creating blind spots and manual work. Redlist’s Integration Hub connects all your systems into one seamless reliability platform:

ERP & SCADA Connectivity

Link field data with your enterprise ERP and SCADA systems. Eliminate manual double-entry and keep corporate and field teams aligned.

IoT & Sensor Integration

Bring vibration, temperature, pressure, and acoustic sensor data directly into Redlist. Gain a single dashboard for real-time condition monitoring and alerts.

Oil Analysis & Lab Data

Automate oil sampling imports from third-party labs. Catch contamination or wear trends without waiting for manual reporting delays.

OEM Manuals & Vendor Systems

Digitally integrate OEM documentation and vendor portals so maintenance teams always have the right specs, instructions, and supplier connections at hand.

Scalable Multi-Site Rollouts

Standardize integrations across upstream, midstream, and downstream sites. Ensure consistent visibility and benchmarking, no matter how dispersed your operations are.

Want to See How Integrations Drive Reliability? Watch our on-demand webinar: Get the Most Out of Your Lubrication Management Program with Redlist Integrations

Key Benefits Section:

Minimize Production Disruptions

Prevent unplanned shutdowns with proactive monitoring and automated PM workflows.

Enhance Workforce Competency

Shorten training timelines from weeks to days using built-in SOPs and visual task guidance.

Improve OEE & Asset ROI

Align maintenance with capital planning to extend equipment life and reduce total cost of ownership.

Technical Specifications

| Specification | Value / Details |

|---|---|

| Deployment | Cloud-based with iOS/Android apps; Offline mode |

| Integrations | ERP, SCADA, OEM manuals, IoT sensors, oil analysis labs |

| Security | SOC2 compliant, role-based permissions, encrypted data |

Where and how is Redlist used?

Upstream Oil Production

Route-based lubrication and preventive maintenance of drilling rigs, mud pumps, and compressors.

Midstream Transport & Storage

Monitor asset health for pipelines, storage tanks, and loading systems.

Downstream Refining

Digitally manage inspections, cleaning schedules, and equipment health analytics across refinery units.

Case Studies

Oil & Gas Company Becomes Model for DEQ Compliance

An oil and gas operator used Redlist to digitize inspections and lubrication tasks, achieving full regulatory compliance and avoiding costly fines while boosting uptime.

Mining Company Saves $270,000 Per Year with Fluid Tracking

By integrating oil analysis and digitizing lubrication management, this customer eliminated fluid loss and achieved major cost savings—results directly applicable to oil and gas operations.

Gold Mine Increases Employee Advancement and Retention

This mining operation leveraged Redlist’s training progressions to improve workforce skills and retention—an approach that addresses labor shortages in oil and gas.

Frequently Asked Questions (FAQ)

How does Redlist integrate with our existing oilfield systems?

Our Integration Hub connects with ERP, IoT sensors, OEM manuals, and oil analysis data for a unified asset view.

Can it be used in remote operations?

Yes. Redlist works offline, storing data locally until an internet connection is available.

How quickly can we be operational?

Most oil and gas sites are fully deployed in under 100 days.

Ready to transform your oil and gas maintenance program?