Purpose-Built Maintenance Software for the Mining Industry

Revolutionizing Maintenance in Mining Industry with Reliability-Centered Software

Mining companies operate in some of the world’s harshest conditions—downtime isn’t just inconvenient, it’s expensive. Redlist is a field-first, offline-capable maintenance platform that gives mining companies a complete toolkit for reliability-centered maintenance, from lubrication and inspections to IoT-based condition monitoring and training.

Engineered for mining reliability teams, operators, and asset managers, Redlist unifies all strategies—preventive, predictive, corrective, and autonomous—into a single system. Our platform equips every employee with mobile, intuitive tools to complete critical maintenance, monitor asset health, and eliminate surprises.

Key Features for the Mining Industry

Integrated Preventive & Predictive Maintenance Scheduling

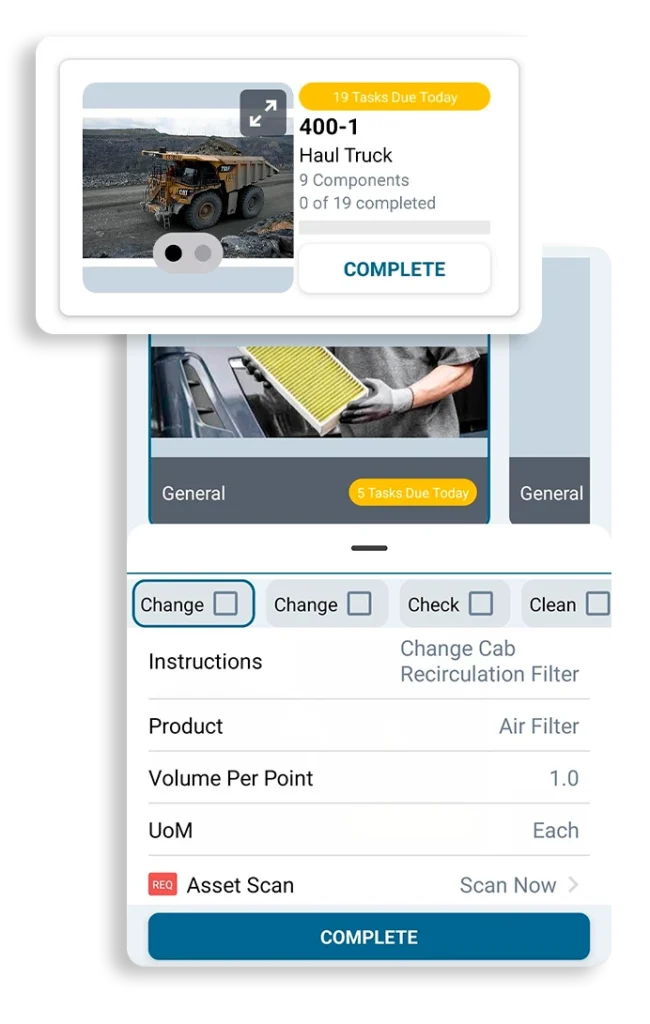

Digitally schedule, assign, and verify lubrication and inspection routes with automated reminders, exception flags, and proof-of-presence tracking. Integrate IoT sensor data for predictive alerts based on vibration, oil analysis, and temperature anomalies.

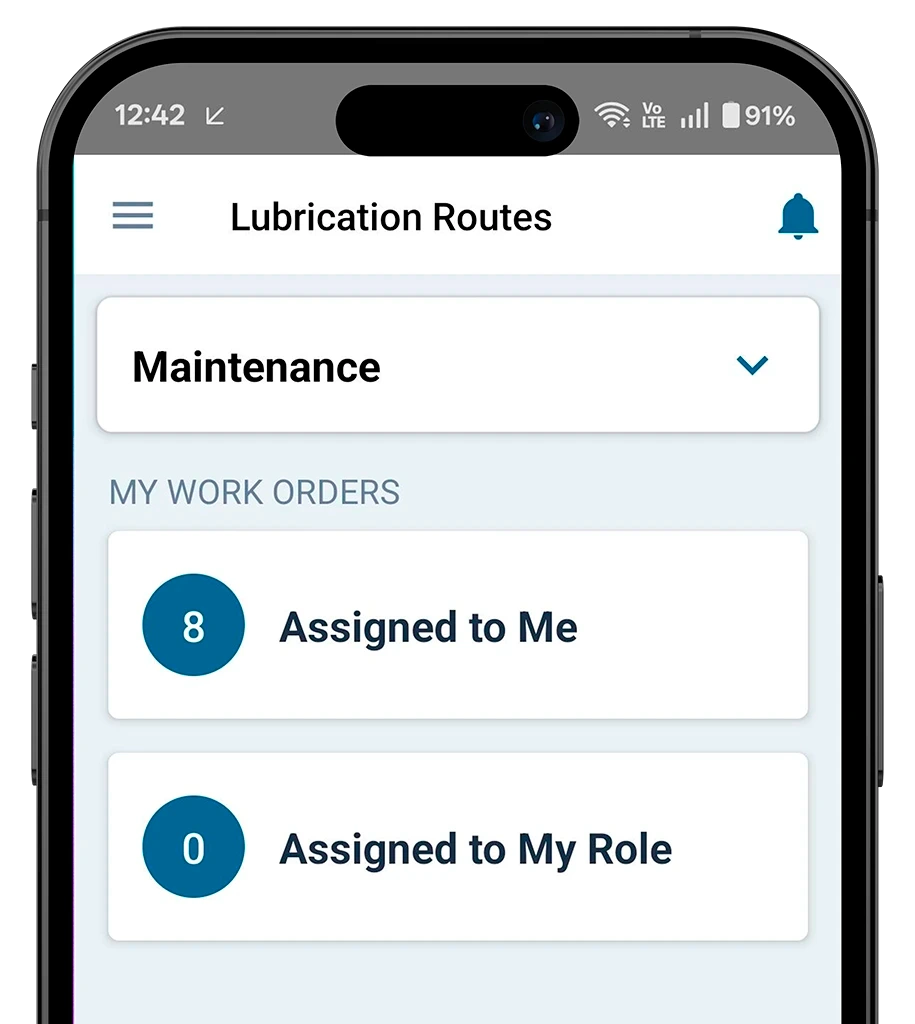

Mobile Inspections and Work Orders—Even Offline

Technicians in remote mining locations can complete inspections, CIL (clean-inspect-lubricate) checklists, and corrective repairs from a tablet—even with no network. Data auto-syncs when reconnected.

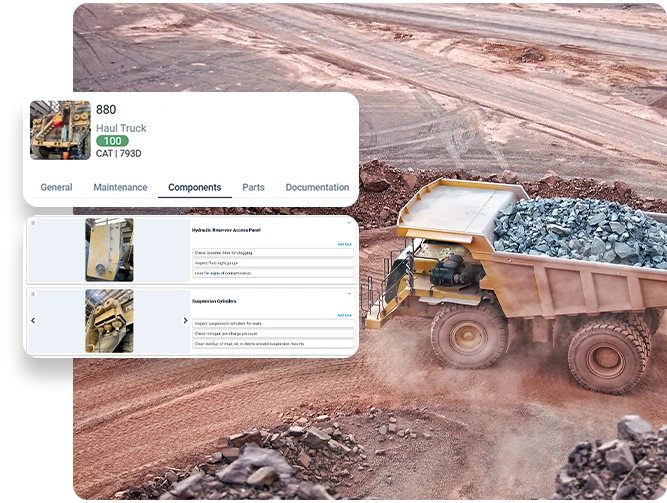

Digital Twin & Asset Visualization

Use Digital Twin Modeling to map and visualize assets—from conveyors to crushers—so even new hires can locate equipment, understand SOPs, and access reliability history instantly.

IoT and Oil Analysis Integration

Connect Redlist to your sensor ecosystem or use oil sampling data to predict equipment degradation. Dashboards highlight emerging failures before they happen, enabling proactive intervention.

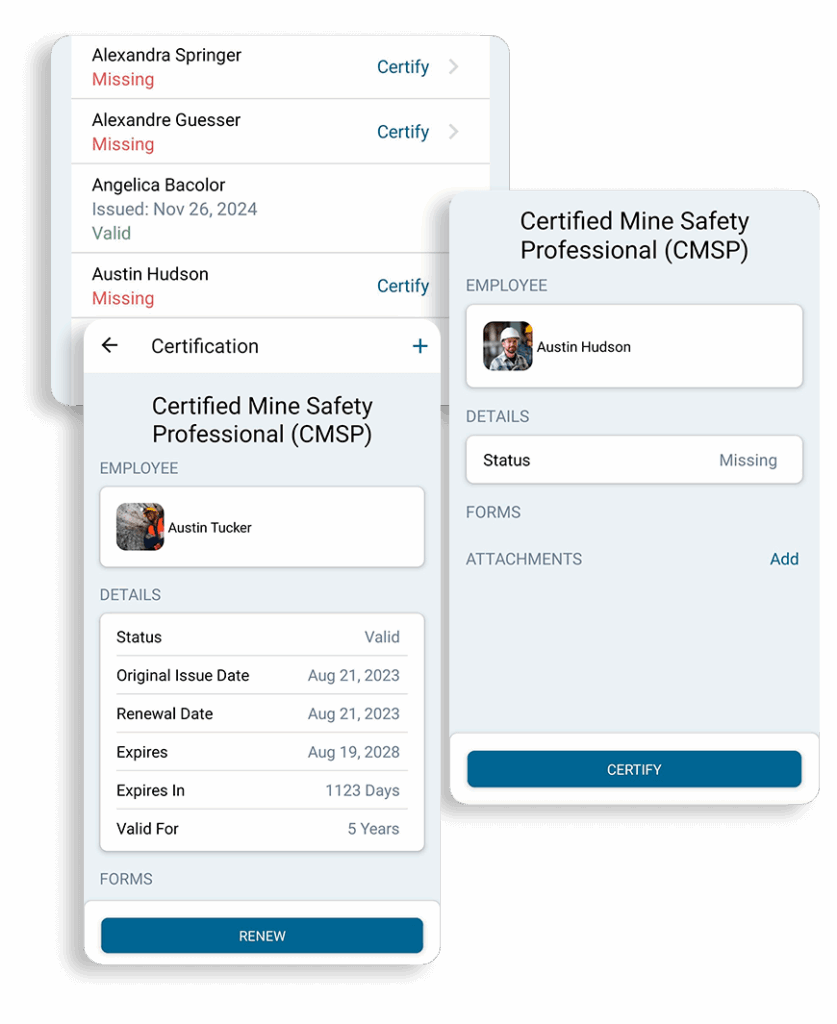

Technician Skill Tracking and On-the-Job Training

Certify employee progression using Redlist’s integrated training modules. Enable just-in-time instructions at the task level and build cross-functional capabilities across reliability and operations teams.

Enterprise-Ready Integrations

Plug into existing ERP, SCADA, and inventory systems via Redlist’s Integration Hub. Centralize asset data and reduce manual data entry across departments.

How Redlist is Transforming Maintenance in the Mining Industry

Redlist provides a comprehensive approach to modern mining empowering reliability teams, operations managers, and plant leadership.

Lubrication Management (LMS): Reduce Downtime in Harsh Environments

Automated Lubrication Routes for Haul Trucks and Surface Equipment

Underground Lube Point Assignment and Verification

Integrated Lubrication Schedules for Mineral Processing Equipment

Fleet and Fixed Asset Standardization

Digital Compliance with MSHA and Site SOPs

Operator Basic Care (OBC): Empower Autonomous Maintenance in the Field

CIL Checklists Built for Harsh Mining Conditions

Offline-Ready Inspections for Remote Sites

Real-Time Workflow Integration Across Departments

Instant Failure Reporting and Escalation Paths

Operator-Centric UX That Drives Engagement

Asset-Level Accountability and Task Histories

Build a Culture of Care in the Pit and Plant

Enterprise Asset Management (EAM): Extend ERP Value from Pit to Plant

Centralize Asset History Across All Equipment Classes

Visualize Equipment in 3D and by Location

Monitor Hours, Cost Centers, and Maintenance Spend

Connect Operations, Maintenance, and Procurement Teams

Drive Lifecycle Planning with Real-Time Asset Intelligence

Predictive Pro: Real-Time Condition Monitoring That Prevents Catastrophic Failures

Monitor Vibration, Temperature, and Noise in Real Time

Integrate Oil Sampling for Fluid Health Diagnostics

Consolidate Multi-Source Condition Data into One Dashboard

Trigger Automatic Work Orders Based on Predictive Data

Support Advanced Root Cause Analysis (RCA)

Optimize PM Frequencies Based on Condition Trends

Redlist helps you evolve from calendar-based PMs to condition-based maintenance. As trend data accumulates, you can safely extend maintenance intervals on healthy components—or proactively intervene before failure risk rises—reducing labor and downtime without increasing risk.

Workforce Automation: Train and Empower Technicians in Any Mine

Step-by-Step Visual SOPs for Any Environment

Role-Based Training Progressions

Redd: Your AI Maintenance Co-Pilot

Support for Multilingual and Visual Learning Styles

Eliminate Reliance on Tribal Knowledge

Ensure Consistent Work Quality Across the Fleet

Lightning-Fast Deployment: Be Operational in Record Time

Seamlessly Import Asset Hierarchies from Your ERP

Digitize OEM Manuals and Preventive Maintenance Schedules

Configure Mobile Workflows Without Outside Consultants

Deploy at Greenfield or Brownfield Sites with Confidence

Scale Rapidly Across Teams and Locations

How does Redlist benefit your Mining operation?

Cut Unplanned Downtime by 10%+

Redlist’s lubrication and inspection tools are proven to deliver significant downtime reduction in active mining operations.

Empower and Retain Workers

Use built-in certifications, just-in-time training, and digital work guidance to motivate and upskill employees—decreasing turnover and onboarding time.

Improve Asset Health Monitoring

Gain real-time visibility into asset performance using integrated IoT, predictive analytics, and digital twins.

Technical Specifications

| Specification | Value / Details |

|---|---|

| Deployment | Cloud + Offline Mode (iOS/Android) |

| Modules Included | 21 total: EAM, OBC, LMS, Predictive Pro, etc. |

| ERP Integration | Plug-and-play via Integration Hub |

| IoT & Sensor Support | Full condition monitoring support |

| Data Security | SOC2 Ready, role-based access, encrypted storage |

Where and how is Redlist used?

Open-Pit and Underground Mines

Preventive and predictive maintenance on mobile fleets, crushers, conveyor systems, and ventilation equipment.

Mineral Processing Plants

Full asset lifecycle and lubrication management for fixed equipment in milling, flotation, and tailings operations.

Remote Mining Operations

Offline-capable data collection and work completion across multiple locations, synced into a centralized reliability platform.

What do real mining companies say about Redlist?

Gold Mine Company Boosts Employee Advancement and Retention with Redlist

An employee advancement program with Redlist saves this gold mine tons of administrative work and increased employee skills and retention.

Mining Company saves $270,000+ Per Year With Fluid Tracking

Redlist’s new tracking software helped a mining company reduce costs and improve safety. Learn how they implemented the CMMS solutio.

Customer eliminates $200,000 in annual MSHA fines

As a result, their field team provided them with the real-time reports they needed to enhance their MSHA compliance.

Frequently Asked Questions (FAQ)

How does Redlist support condition monitoring in the mining industry?

Redlist integrates IoT sensors and oil analysis data into your maintenance workflows to predict failures before they occur and eliminate surprises.

Can Redlist run in remote mines with no internet?

Yes, our mobile app works fully offline. Data is stored securely and syncs once a connection is available.

How long does it take to implement Redlist at a mine site?

We can fully deploy your reliability strategy—including ERP integration, training tools, and digital routes—in less than 3 months.

Ready to Maximize Asset Life?