Redlist: Marine Fleet Management Software That Maximizes Vessel Reliability

Purpose-Built for Marine Reliability

The marine industry operates under unforgiving conditions—saltwater corrosion, heavy loads, tight schedules, and strict compliance requirements. Downtime isn’t just costly; it can disrupt global supply chains and compromise safety.

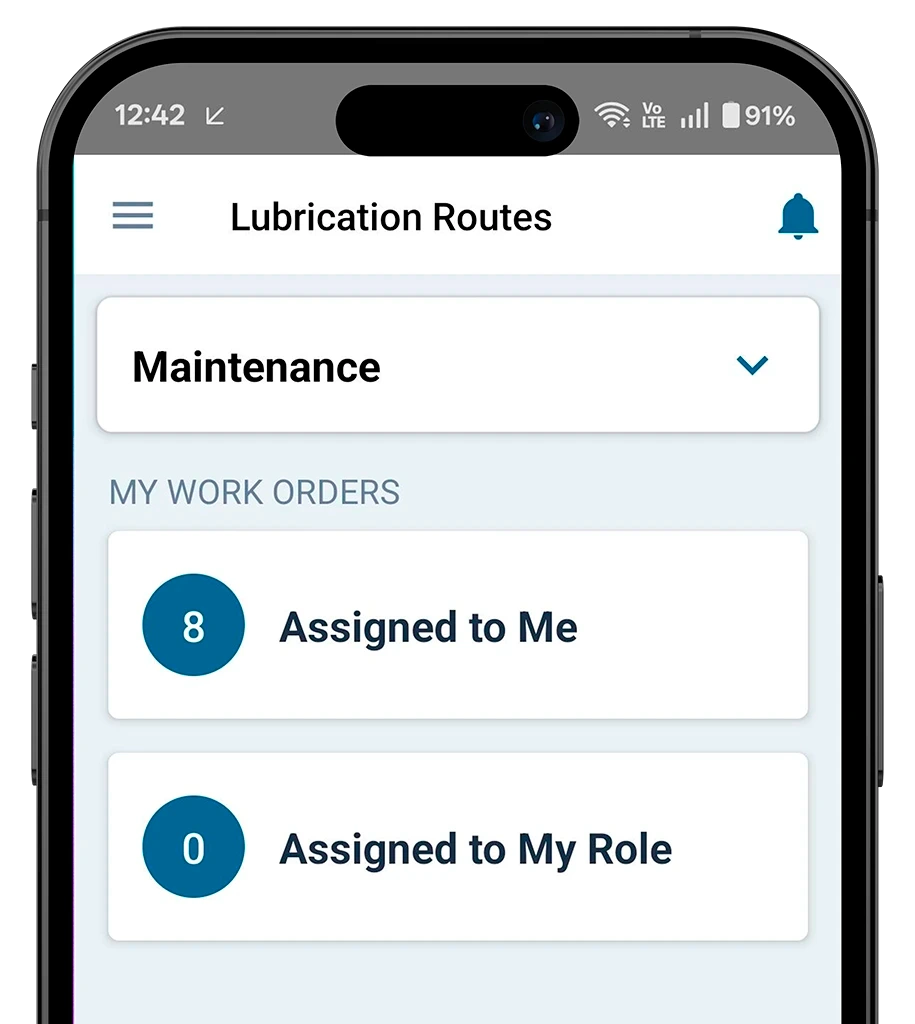

Redlist’s marine fleet management software gives ship operators, port authorities, and reliability teams a unified system to manage preventive maintenance, condition monitoring, lubrication, and training. With offline mobile capability, integration to ERP and IoT sensors, and digital SOPs, Redlist ensures that every vessel, crew member, and component operates at peak performance.

Core Features for Marine Operations

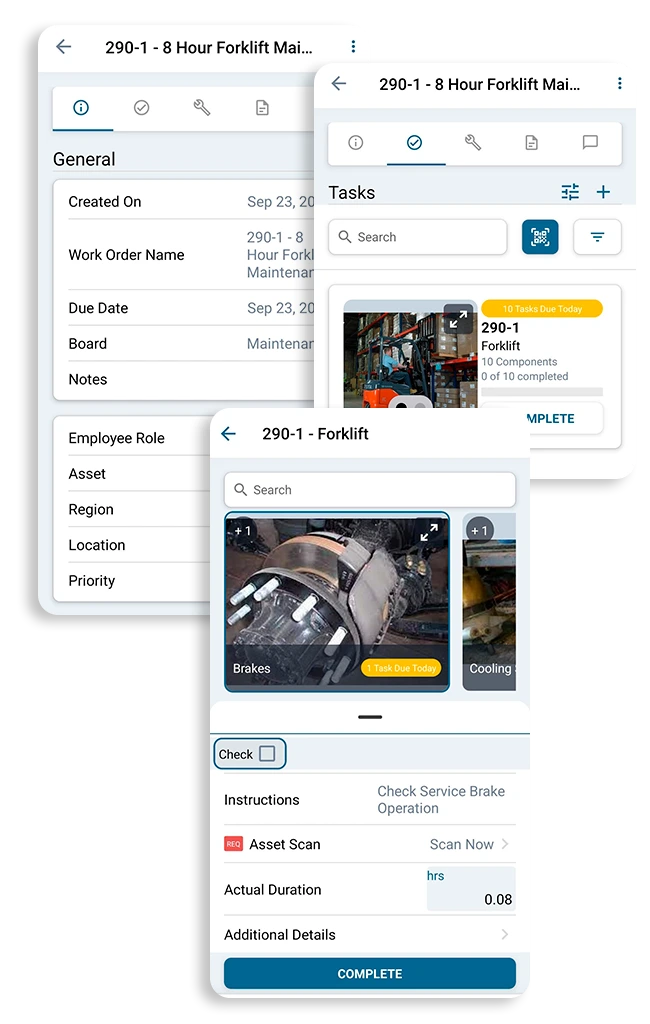

Preventive & Predictive Maintenance Scheduling

Offline-Ready Inspections

Lubrication Management

Digital Twin Vessel Visualization

Crew Training & Certification Tracking

ERP & IoT Integrations

What Sets Redlist Apart in Marine Maintenance

Lubrication Management (LMS): Prevent Failures from Propulsion to Deck Equipment

Improper lubrication is one of the leading causes of marine equipment downtime, from propulsion systems to auxiliary pumps. Redlist ensures lubrication compliance across vessels and fleets.

Automated Lubrication Routes for Propulsion and Auxiliary Systems

Standardize greasing on engines, gearboxes, winches, and hydraulics. Prevent skipped points with digital completion tracking and photo-verified proof.

Oil Analysis Monitoring for Marine Conditions

Integrate lab results on wear metals, water ingress, or fuel dilution. Get automated alerts when conditions indicate abnormal wear.

Compliance-Ready Digital Logging

Automatically capture lubrication tasks for IMO, USCG, or class society audits. Eliminate paper logs and reduce inspection time.

Fleet-Wide Standardization Across Vessel Types

Apply consistent lubrication practices whether managing tankers, ferries, or offshore supply vessels—simplifying training and reducing errors.

Want to see how lubrication management cuts costs?

Operator Basic Care (OBC): Empower Every Crew Member in Vessel Reliability

Onboard crews are the first line of defense against failures. Redlist equips them with practical tools for daily reliability.

Digital CIL Checklists for Machinery Rounds

Provide Clean, Inspect, Lubricate checklists tailored to shipboard assets like ballast pumps, generators, and compressors.

Offline Inspections While at Sea

Crews can log issues without internet—photos, notes, and digital signatures sync automatically in port.

Rapid Anomaly Capture and Escalation

Log unusual vibration, leaks, or overheating directly from a mobile device. Issues route instantly to engineers for follow-up.

Operator-Centric UX

Large icons, visual instructions, and intuitive flows mean even new crew can confidently perform tasks from day one.

See how Redlist supports Operator Basic Care across industries.

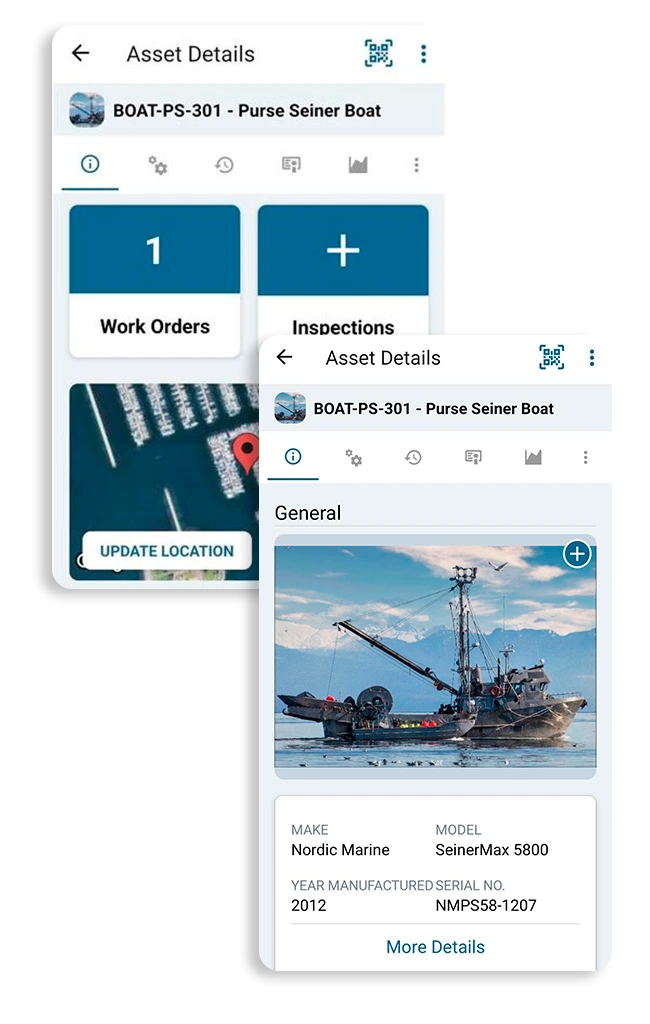

Enterprise Asset Management (EAM): Centralized Visibility Across Your Fleet

Marine ERP systems aren’t built for frontline reliability. Redlist fills the gap with a fleet-first, field-ready platform.

Unified Asset History for Every Vessel

Track inspections, lubrication, failures, and repairs across propulsion, navigation, and safety systems.

Digital Twin Vessel Modeling

Visualize ship layouts to locate equipment, SOPs, and maintenance backlogs instantly.

Maintenance Spend Tied to Voyages

Connect work history and costs to specific voyages or cost centers for better ROI planning.

Bridge Operations, Maintenance, and Procurement

Ensure everyone from the engine room to corporate HQ works from the same data stream—no silos, no spreadsheets.

Discover how Enterprise Asset Management bridges ERP and frontline operations.

Predictive Pro: Condition-Based Intelligence for Marine Assets

Prevent catastrophic failures at sea with real-time condition monitoring.

Real-Time Sensor Integration

Capture vibration, temperature, and acoustic data on engines, turbines, and rotating equipment.

Oil Sampling Linked to Components

Automate lab imports for viscosity, particulate count, and water contamination—building a complete picture of asset health.

Predictive Alerts with Automatic Work Orders

Threshold breaches instantly generate work orders with SOPs attached, closing the loop from data to action.

Support for Root Cause Analysis (RCA)

Combine sensor data with technician notes to analyze why failures occur and prevent repeat issues.

Learn how Predictive Pro transforms condition monitoring by reading this

Workforce Enablement: Train and Retain Marine Crews Faster

Labor shortages and high crew turnover demand faster training and better retention tools.

Digital SOPs at the Task Level

Step-by-step instructions with images and videos accessible on any device—even offshore.

Certification Tracking for STCW and Class Requirements

Automate certification renewals and track compliance for every crew member.

AI-Powered Maintenance Co-Pilot (Redd)

Crews can ask questions, access SOPs, and troubleshoot issues instantly without waiting for a supervisor.

Support for Multilingual & Visual Training

Deliver instructions in preferred languages and visual formats, supporting a global, diverse workforce.

See how Redlist accelerates crew competency and increases employee retention through this

Lightning-Fast Deployment: Operational Across Fleets in Record Time

Marine operators can’t afford long IT projects—Redlist deploys quickly and scales across fleets.

Import Vessel Asset Hierarchies from ERP

Rapidly sync propulsion, deck, and auxiliary systems into Redlist’s structure.

Digitize OEM Manuals and PM Schedules

Convert existing paper-based ship manuals into actionable digital tasks.

Configure Without Consultants

Build and adapt vessel-specific workflows through Redlist’s no-code interface.

Fleet-Wide Rollouts at Scale

Standardize across multiple vessels and ports using templated configurations and centralized oversight.

Book a Demo to see how fast Redlist can go live for your fleet.

Key Benefits Section:

Reduce Unplanned Downtime

Prevent failures before they strand vessels.

Ensure Compliance & Safety

Always be audit-ready for IMO, USCG, and class inspections.

Empower Crews

Faster training, reduced errors, and higher retention.

Technical Specs Section

| Specification | Value / Details |

|---|---|

| Deployment | Cloud-based + Offline Mode (iOS/Android) |

| Modules Included | 21 total: LMS, OBC, EAM, Predictive Pro |

| ERP Integration | Plug-and-play via Integration Hub |

| IoT & Sensor Support | Vibration, temperature, acoustic, oil analysis |

| Security | SOC2 compliant, role-based access |

Where and how is Redlist used?

Commercial Shipping Fleets

Offshore Platforms & Supply Vessels

Passenger Ferries & Cruise Ships

Case Studies

Fluid tracking saves $270,000 annually

Operator training boosts employee retention and safety.

Frequently Asked Questions (FAQ)

Can Redlist work when ships are offshore without internet?

Yes. Redlist’s offline-first mobile app stores all data and syncs once connectivity returns.

How does Redlist integrate with existing fleet management systems?

Through the Integration Hub, Redlist connects to ERP, IoT sensors, OEM manuals, and oil analysis labs.

How quickly can Redlist be deployed across a fleet?

Most marine operators are fully operational within 100 days.

Join shipping companies, offshore operators, and marine fleets already using Redlist to cut downtime, simplify compliance, and boost profitability.